Lot Management

Description

Lot management should be an integral part of inventory management for companies that require traceability of all components/materials/ingredients in case of a product recall. Ascent gives companies the ability to perform quick analysis of what supplier provided what lot, what customers were shipped products which contained possible contaminated lots, and what products are in inventory that are of lots which have been recalled, thus reducing research time and allowing corrective action to be taken quickly.

In the United States, the FDA (Food and Drug Administration) has specific requirements around a recall, and Ascent assists with adherence to those requirements.

By managing lots that have a receipt date and a “good through” date, companies can ensure that only quality material is used in manufacturing or shipped out to customers. Expired lots can be segregated in Ascent and not available for use.

Terminology

| FIELD | DESCRIPTION |

| Lot Number | An identification number or code assigned to a batch of products. |

| Product | The item offered for sale. |

| Lot Status | Status of a specific product quantity or batch of products quantities. |

| Expiration Date | The expiration date of the lot. |

| Stocking Unit Quantity | Total unit quantity products that are available in a specific lot. |

| Cost | Cost of the product received. |

What is a lot?

A lot is a quantity of material purchased (or manufactured), usually at one time. A company may purchase beige paint on Monday and the same beige paint on Friday. However, there could be slight differences in hue. The supplier would assign a lot name to Monday’s delivery and a different lot name for Friday’s delivery. This differentiation is very important, and one might not want to mix lots, for fear of getting slightly different hues. This becomes even more important when purchasing a food product or something which is ingestible, like a chemical (a component of some pharmaceutical). If there is a recall, there would be a need to not only identify lots that are being recalled, but what products that lot went into. Therefore, upward lot tracking (what did this lot become part of) is critical to identifying which customers have finished product that a recalled lot went into.

A lot’s quantities can be split into multiple locations, since there might be space limitations on an individual location. Lots can also have their own cost, which would be recorded when received on a purchase order or manufactured.

Lot tracking is optional by product, so if packaging and cleaning solvents, for example, have infinite shelf life, no lots are required to be created or tracked for those.

Lots can have a shelf life, meaning that they are only considered available and usable within a period of dates. These dates can be established upon initial recording of material into the system. Once lots have expired, they are no longer available to be shipped to a customer nor used in any manufacturing processes. Lots that are ready to expire or have expired can be easily singled out and action can be taken. Additionally, lots that are within acceptable date limits can be quarantined, just as new lots can be quarantined until appropriate testing and inspection occurs, thus ensuring that only safe lots can be shipped to customers or used in manufacturing.

The shelf life can be determined by product, which can have the number of expiration days, such that, for example, if the number of expiration days is 90, a lot recorded on January 1, 2020 will expire on March 31, 2020.

Inventory Controls Strategies, Stock Rotation Methods

There are several ways to ensure that oldest lots are picked for customer orders first. One way is FIFO (first in first out), and another way is FEFO (first expired first out). When the time comes to pick material, the system will present available lots based on which administrative setting is chosen, FIFO or FEFO. Of course, LIFO (last in first out) is also possible, however minimally used for lot tracked products.

If you are decided to use lot management, Ascent provides the flexibility to show the proper available inventory based on your stock rotation priority while picking and packing the orders. For example, if when packing the order you want to show the oldest available inventory first then you can set the lot management setting to FIFO, so that the oldest received products will be sold first.

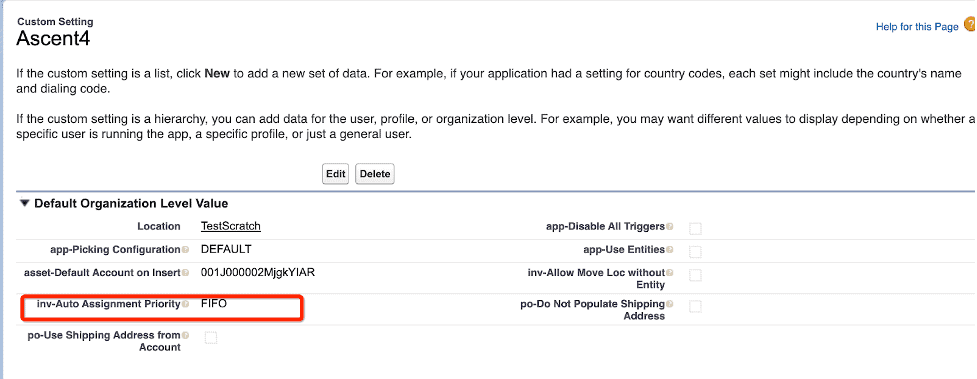

You can follow the below steps to setup this values:

- Go to Setup

- Search for custom settings

- Click on manage next to the Ascent4 custom setting

- Set the inv-Auto Assignment Priority

- Accepted values are FIFO, FEFO, LIFO and GREATEST

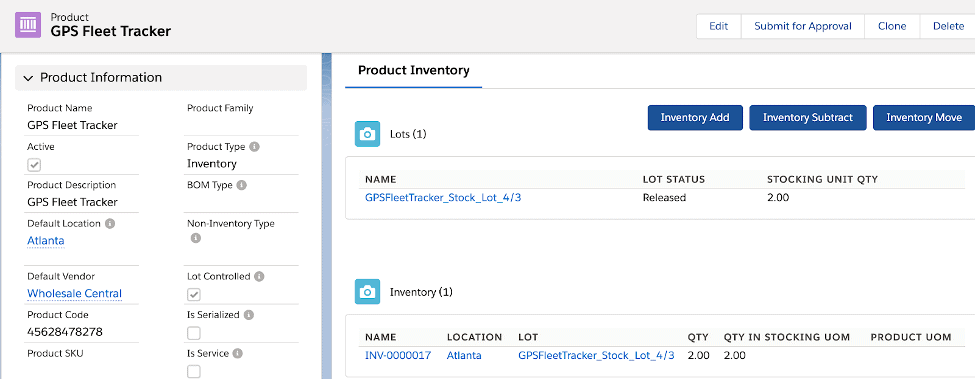

Lot Controlled Product

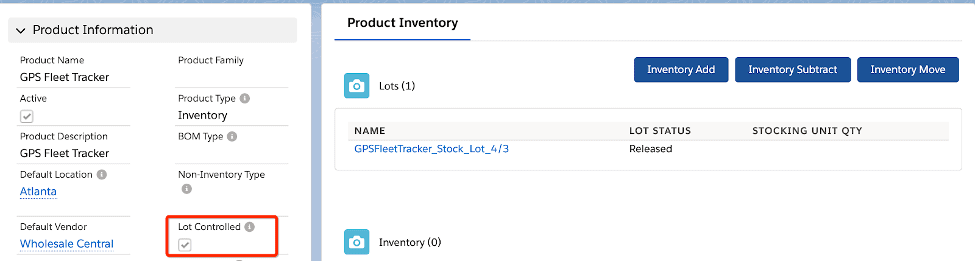

When you are creating a product, if you want this product to be tracked using lots within the inventory, then you need to set the “Lot controlled” checkbox to true.

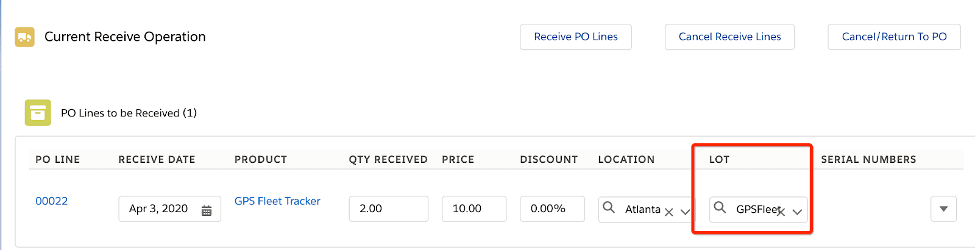

Receive a Purchase Order with lot controlled products

- Create a purchase order

- Add purchase order lines with product, quantity and price

- When receiving products it requires you to select location and lot since this product is set as lot controlled

- You can create a new lot to receive the inventory or select the existing lot

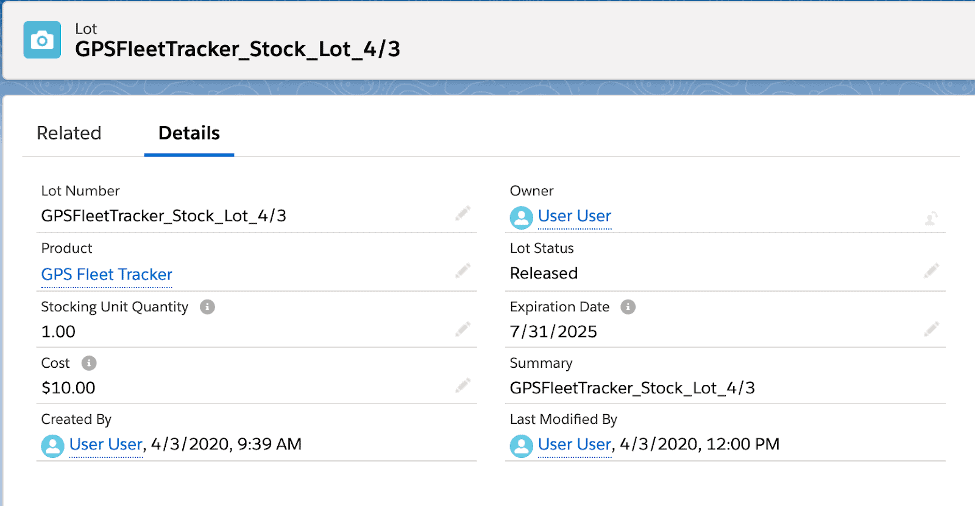

- After the products are received it will update the cost, stocking unit qty on the lot

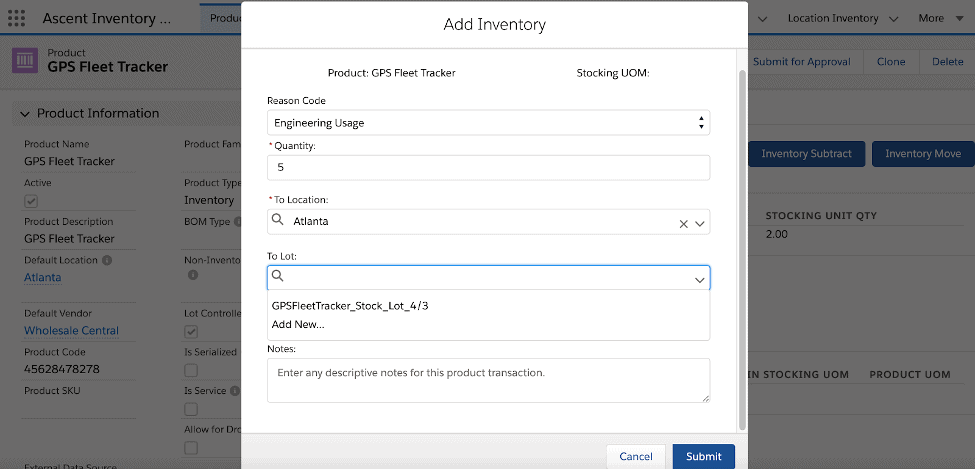

Inventory adjustment for lot controlled product

- Create a product

- Set the product as lot controlled

- Click on Inventory Add

- Select the quantity, Location and Lot

- You have an option to select an existing lot or create a new

- After it is saved it will update the stocking unit qty, cost on the lot

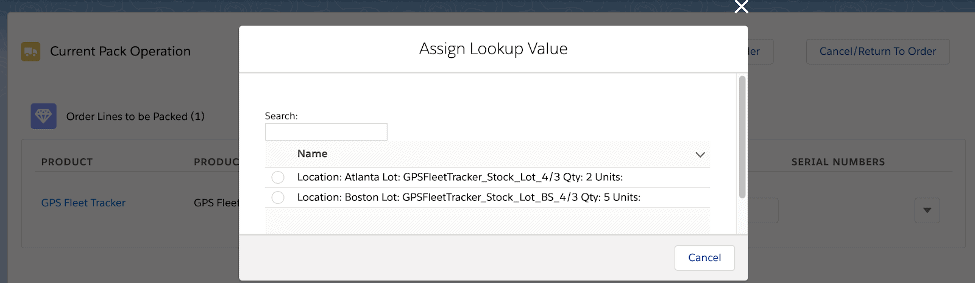

Packing an order with lot controlled products

- Create an order

- Add order products

- When packing an order, it will show all the available inventories in the priority that you selected (like FIFO, FEFO, LIFO or GREATEST)

- Are you not seeing all the available inventory records? Check the expiration date of the lots. This will only show inventory for lots that have not expired.