ERP Enthusiast WIN Digital Solutions Interview

View All: Resources

A Conversation with John Werling, Partner, Director of Operational Excellence Practice at WIN Digital Solutions

In the ERP Enthusiast series, we explore stories from trailblazers within the Salesforce ecosystem that are connecting front-office and back-office operations natively on the platform. This week we discuss Salesforce engineer-to-order (ETO) native approaches on the platform.

John, how did you become an ERP enthusiast within the Salesforce ecosystem?

Previously, I was the director of Operational Excellence at a consulting firm in Pittsburgh, facilitating Lean and Six Sigma initiatives as a Lean Sigma Black Belt with manufacturing clients. I also collaborated with Tom Scuoteguazza, who was deploying enterprise software with some of the same clients and is now Ascent Solutions VP of Customer and Partner Success. Our firm focussed on process-first solutions so the collaboration was a natural fit. One of our first projects together was working with an engineer-to-order (ETO) company that needed an ERP system.

At the time, Salesforce was a rising success story but we didn’t know much about it. We were working with traditional on-premise ERP applications. But I was on the board of a non-profit that was using Salesforce and I got to know the functionality up close. Tom and I both were impressed with the configurability of the platform. So we started collaborating on Salesforce projects. Before long we discovered Ascent ERP and began to focus on the combination of ERP and CRM to build end-to-end inventory lifecycle solutions for clients in the manufacturing, distribution, and non-profit sectors. By the way, I’m also an Ascent Solutions Certified Implementation Partner.

Tell us more about your company WIN Digital Solutions.

WIN Digital Solutions emerged from that firm, World-Class Industrial Network also known as WIN. Founded in 1993, WIN offers consulting and project development services leveraging best practices in process improvement and change management. Over time, technology adoption, and Salesforce specifically, became an increasing share of our client work. WIN Digital was launched from our IT practice, and while the WIN Digital brand is new, as a team we’ve offered services for 15 years – including progressive technology planning, solution design, systems integration, and implementation services to small and medium-sized companies.

Let’s talk more about how engineer-to-order (ETO) companies utilize Salesforce. Can you add more detail?

Sure, for people who may not know, ETO companies do a lot of custom creation for their customers. Unlike standard product companies, you build a bill of materials (BOM) on the fly, tailored specifically to a customer’s specifications. From an operations perspective, ETO is more project-oriented and less routine than a production environment. In contrast with standard widgets built with standard components, ETO companies typically start with a bare chassis and add features and options to order.

Because of the amount of customization, the other nuance is the degree to which they buy/build-to-order vs. buy/build-to-stock. The truth is that most companies are “tweeners,” employing both strategies in a mixed environment. It is a pretty different process model than is presented by a standard item master ERP, because of the variation and varying sequence of activities needed to specify, confirm, and ultimately fulfill an order. So we’ve created some pretty cool modifications using Ascent ERP as the core application to extend Salesforce and facilitate a more flexible product and process model. These can encompass all kinds of ETO products from custom furniture to custom renovations. Any product you can think of really that is configured-to-order.

That sounds pretty complicated. How do you solve this in a simple and effective way for ETOs on Salesforce?

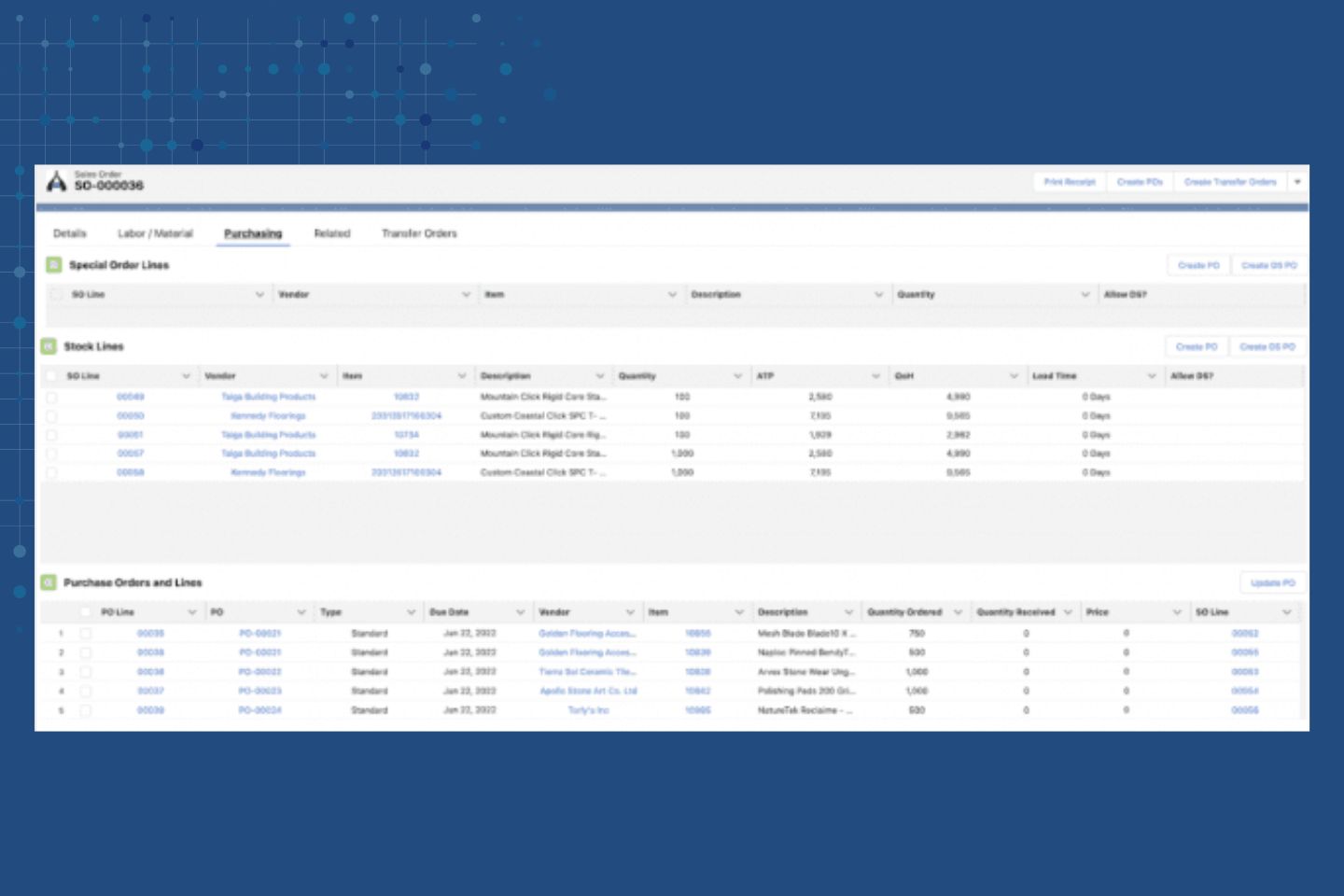

You first have to understand how a standard inventory process aligns with a typical ETO flow. In both environments, all the same order and inventory transactions are required. You have to secure the raw materials and resources to fulfill an order, you have to receive and process those materials and ultimately ship and possibly install the finished product. But the sequence of steps can vary a lot, even for the same customer order. Some of those materials are pulled from stock, others are bought-to-order, maybe even drop-shipped. Some are assembled in the shop, and still others might be assembled on-site. Some may even be a unique one-time-only component. There are dozens of possible scenarios for any single component needed to fulfill an order.

Further, there is typically a lot of back and forth with both customers and vendors to confirm precise requirements. For example, when a customer initially confirms an order, maybe they selected a “mid-grade” floor covering that established the sales price. But before you can ship and install the product, they need to select an exact pattern from dozens of currently available flooring options that are purchased to order from an ever-changing vendor catalog. And perhaps that selection determines what subflooring and adhesive is required. So all of these decisions are in the critical path for order fulfillment. Now multiply that by another half dozen finish options for the entire project and you quickly see the potential complexity.

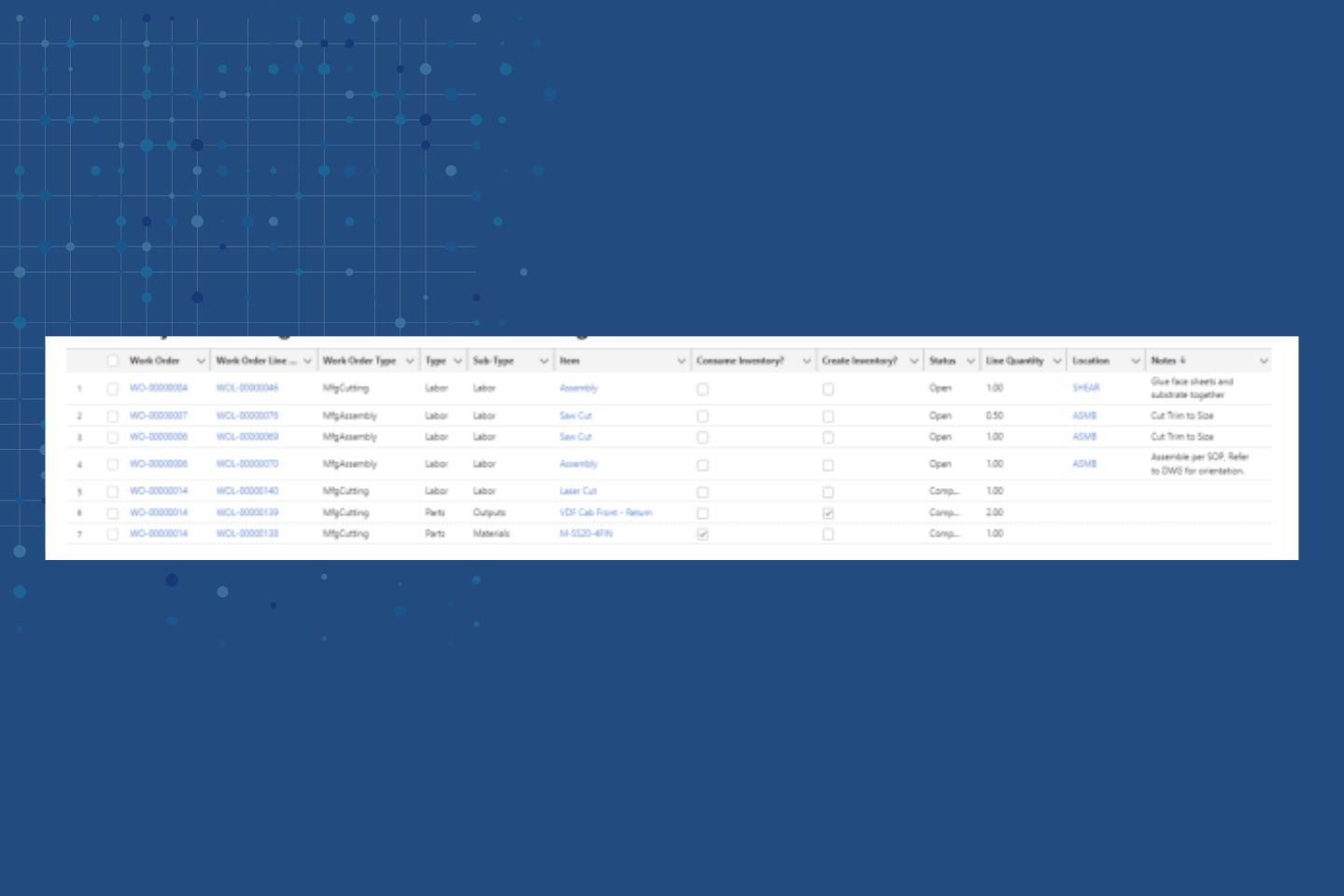

Fortunately, as a CRM the Salesforce platform builds in all kinds of tools and automation to facilitate this kind of iterative and agile communication. We can use tasks with ticklers, and approval processes and establish work queues to direct a team to where their attention needs to be at the right time to fulfill orders on time. We didn’t need to reinvent the wheel because there is a textbook process flow for ETO companies. We simply leveraged the core Ascent ERP application and the Salesforce toolset to facilitate that process through each phase including (1) Sales, (2) Planning & Design, (3) Execution (manufacturing and/or installation), and (4) Post-project. Within each phase, there are specific tasks and transactions required and tools to facilitate those and ensure progress towards key milestones.

Interesting, could you show us what the process flow steps look like using Ascent ERP and Salesforce for an ETO company?

Sure, here are some screenshots of the ETO application in each phase of the process.

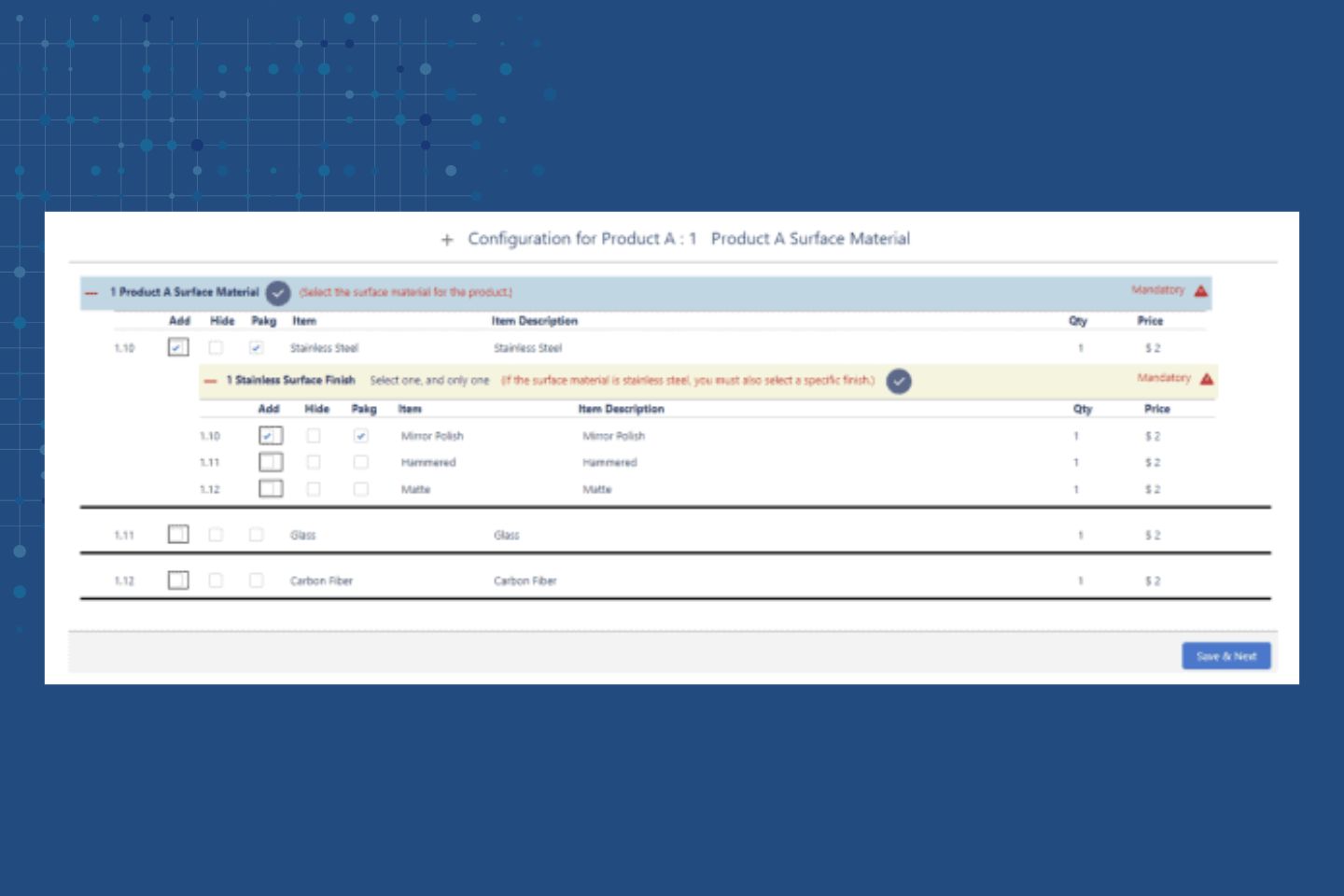

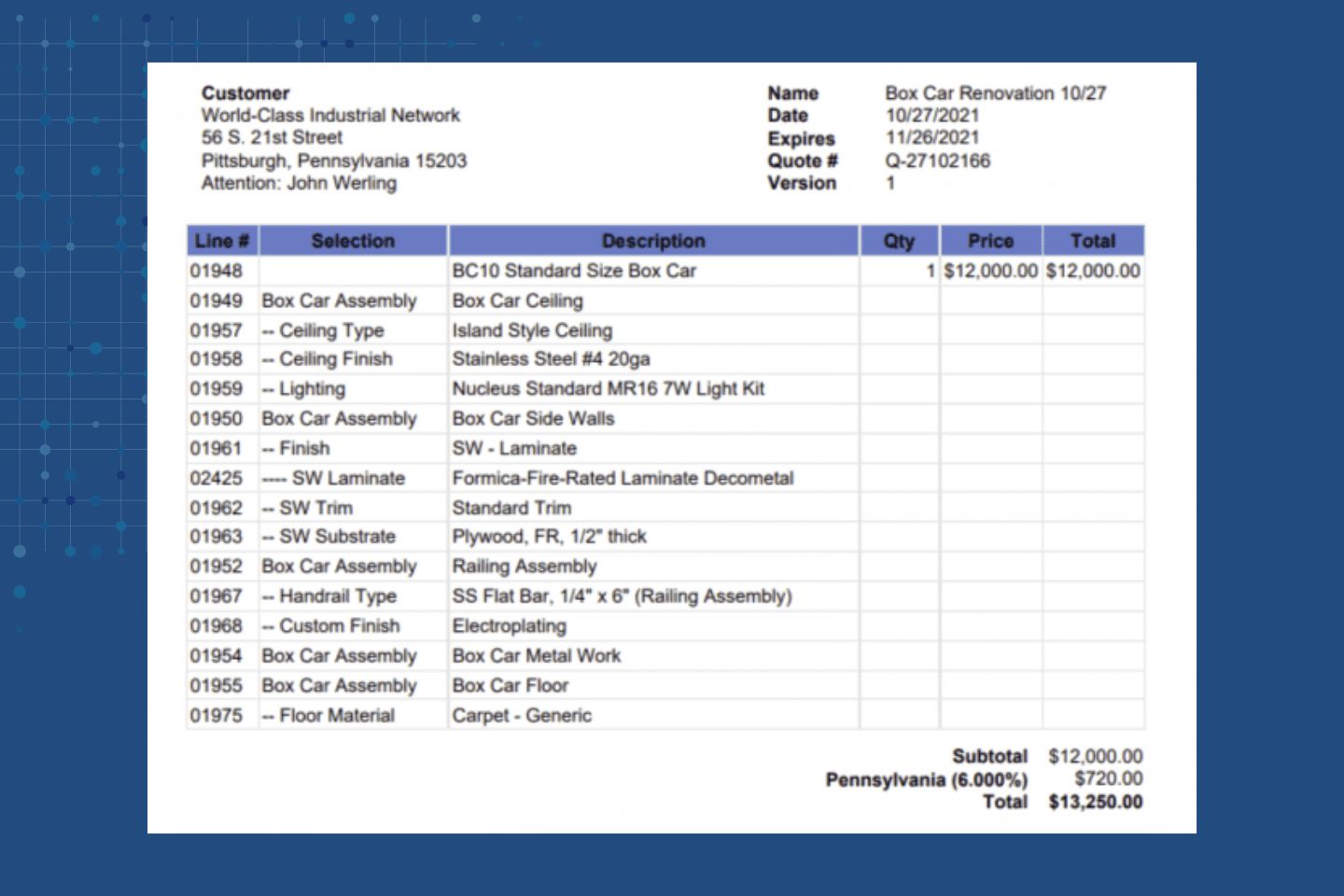

Sales – A custom configuration screen allows for guided sales using dependent multilevel selections of configured options to build a Customer Quote.

Post Project – Salesforce Approval Processes, Ascent Inspection Work Orders, and Action Plans with Punchlist tasks can all be used to facilitate a structured close-out process.

Thanks for sharing your story John and for being an ERP enthusiast!

Learn more about John Werling at WIN Digital Solutions on their website and LinkedIn company page. Make sure to also check out Ascent Solutions’ 100% native apps on AppExchange or contact us to discuss your ERP needs.

Follow Us

Have questions? We can help!

Ascent Solutions will provide you with ultimate customer service, attending to all of your needs promptly and efficiently. Our goal is to serve as your partner so that all of your needs are met in accordance with your schedule and align with your budget.

- Call Us: 908-981-0150

- Ascent: Contact Us

Related Posts

Categories

Why Ascent?

We are distribution and manufacturing technology enthusiasts that understood the term “ERP” was oversold and under delivered. We designed a flexible platform to ensure that we are able to adapt and evolve with businesses from the startup to enterprise level yet keep our offering affordable.