Production Work Order – Material Variance

Overview

This document will serve as an overview of the functionality available via Production Work Orders and the AFP tool to create a production work order, production work order completion, and material variance.

Definition: Material Variance can occur when an item, which is a BOM-non Phantom, has a cost type of “Standard”, is built, and the components’ quantities issued at completion time are not the standard quantities to be consumed, according to the quantity on the BOM. The components do not have to be at standard.

Ascent’s AFP module is required to set up the general ledger accounts and posting processes.

Let’s illustrate the set-up, but assume the general ledger accounts have already been created.

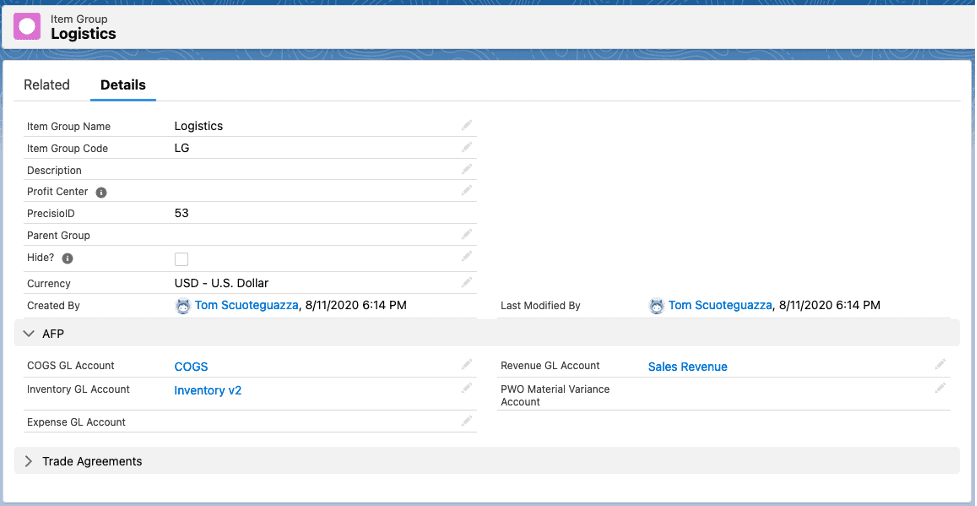

- First, set up the Item Group posting profile. Item Groups are ways that we can categorize items with similar characteristics, like posting accounts, common uses (brass screws, wood screws, etc), and costs.

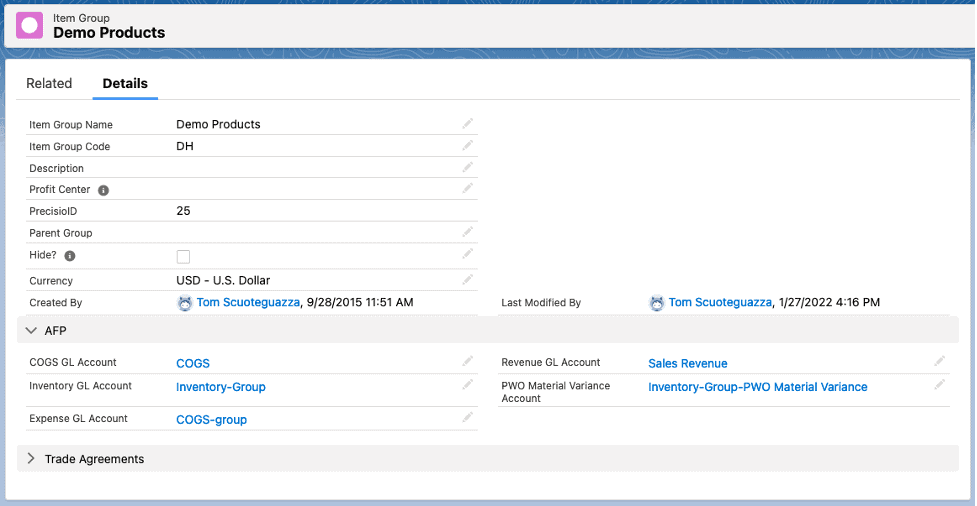

Here, we’ve set up an item group called Demo Products. This item group is the one assigned to our BOM item. To access it, click on the tab entitled Item Groups:

You need an item group name, an up-to-3 character item group code, and the appropriate general ledger accounts. For our example, we require the Inventory GL Account (the one that gets the DR when completing the PWO) and the PWO Material Variance Account (can be a DR or CR), but as you can see, it houses other GL accounts for other purposes.

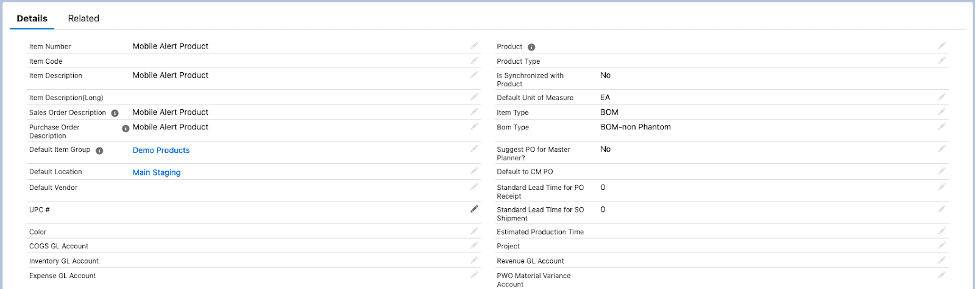

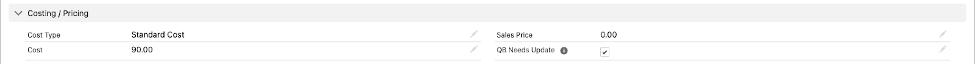

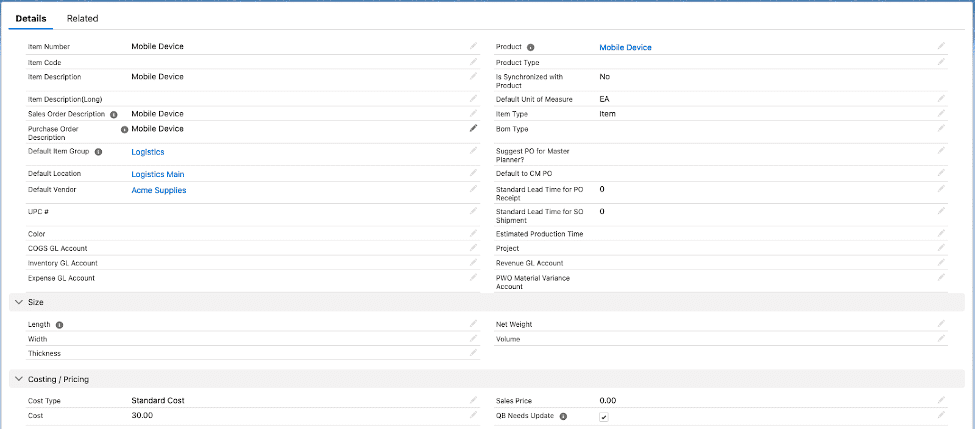

The BOM item itself looks like this – Cost Type is Standard, and the Cost is $90.00:

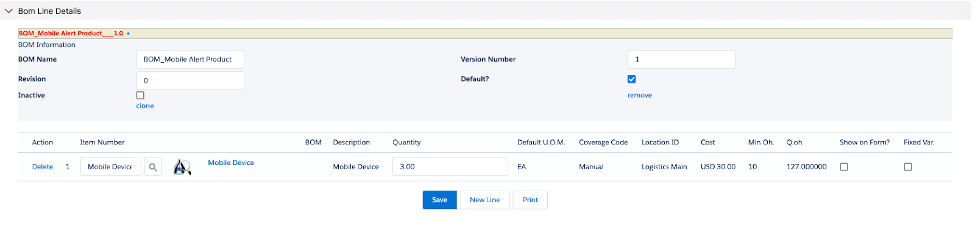

And the bill of materials looks like this – a single item, with a cost of $30.00 per each, but when multiplied by the quantity, results in the cost for the BOM of $90.00.

Now, let’s look at the component:

It has an item group of Logistics:

The account we need to be concerned with here, is the Inventory GL Account. It’s what gets the CR when the PWO is completed.

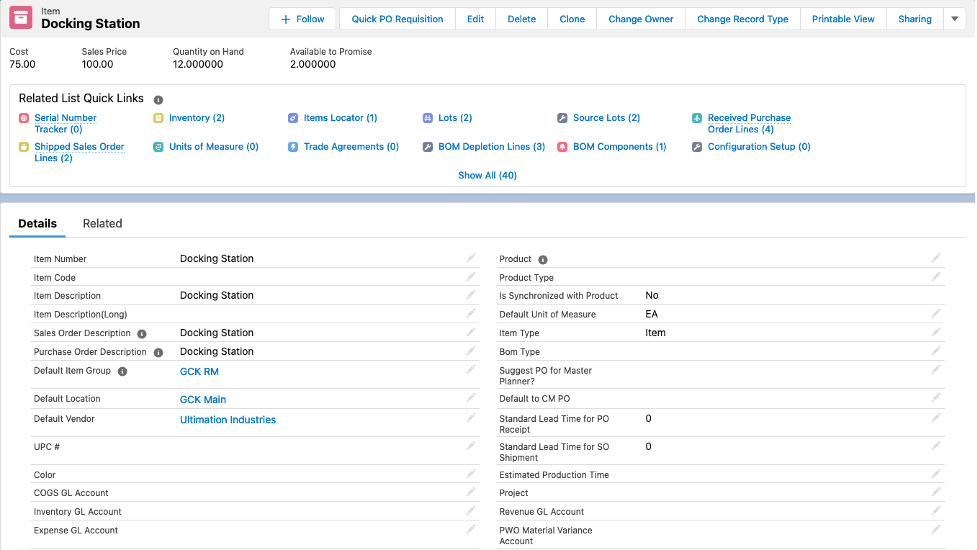

There’s another place where you can put your GL Account, and that’s at the Item Master level. You might have an item (precious metals?) that you wish to have its own inventory account. You can also have those other accounts on the items master that are referenced on the item group. They are referenced at the bottom of the following screenshot:

The above display is a good example, but we will not be using it in our process.

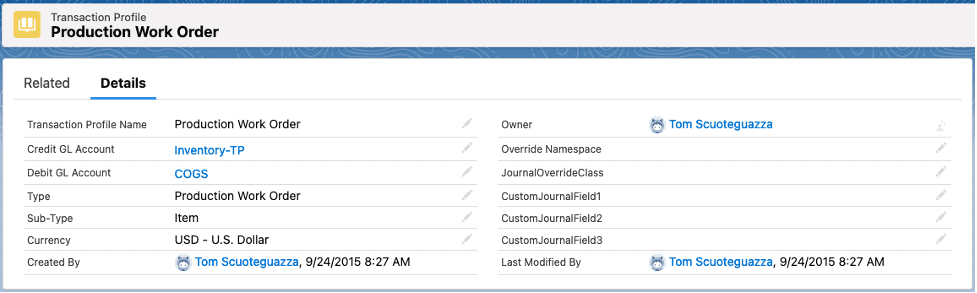

Lastly, there needs to be a transaction profile for the Production Work Order. This is the back-up / default set up of general ledger accounts. Go to the tab called Transaction Profiles and add this one:

Process: To illustrate the creation of purchase price variance journals, we will:

- Create a production work order

- Perform a PWO with the quantity being consumed/issued different than the quantity on the bill of material for the BOM

- Review the journal that was created

Create the Production Work Order:

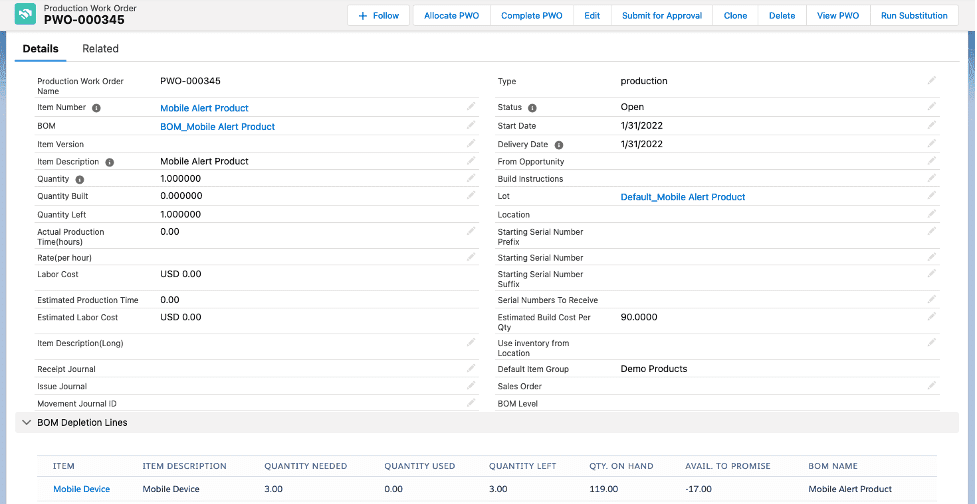

We’ll create a simple production work order. The PWO line will be for an item with a cost of $90.00, with a quantity of one (1). Go to the tab titled Production Work Orders and add a NEW one:

Complete the Production Work Order:

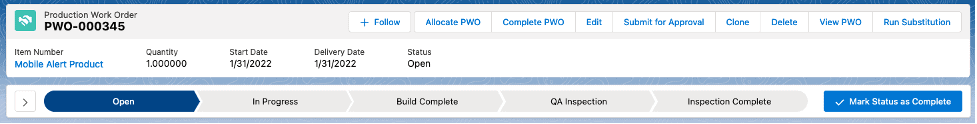

Now, let’s receive the production work order by clicking Complete PWO at the top of the PO screen:

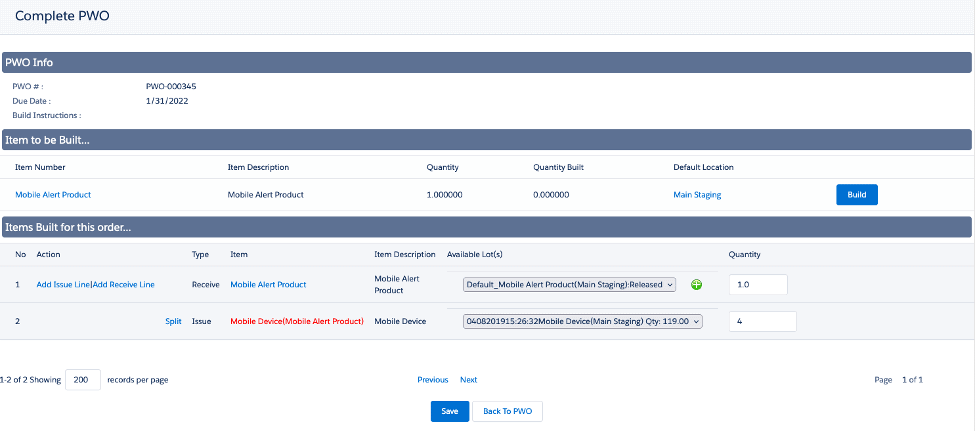

On the next screen, which came up as a result of clicking Complete PWO, we clicked the Build box next to the Item to be Built, and are now being asked to either select the available lots to add the newly built item or create a NEW lot (by clicking the green circle with the + in the middle of it). We’ll accept the default lot/location:

However, we can select the component from several lot/locations. Additionally, we can change the quantity to be deducted from inventory. To demonstrate Material Variance, we must consume more than the standard amount. Let’s deduct 4 rather from 3:

Now, let’s hit Save:

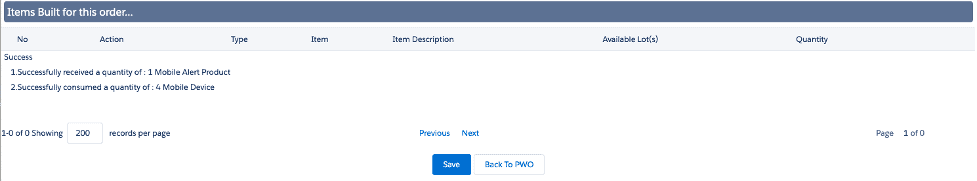

We see that a quantity of 4 was deducted from inventory for the component and a quantity of 1 was added to the finished good.

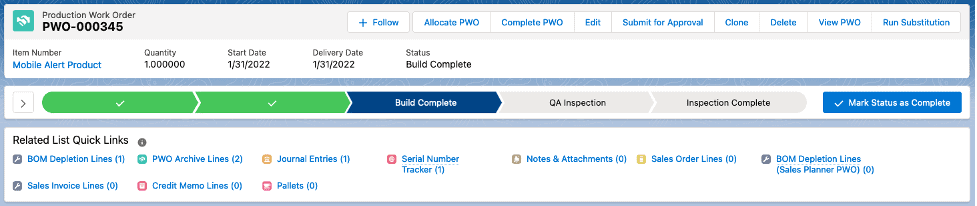

After clicking Back to PWO, we can refresh the screen and look at the Related List Quick Links, where we’ll see Journal Entries (1). Also notice that the status bar has moved to “Build Complete”:

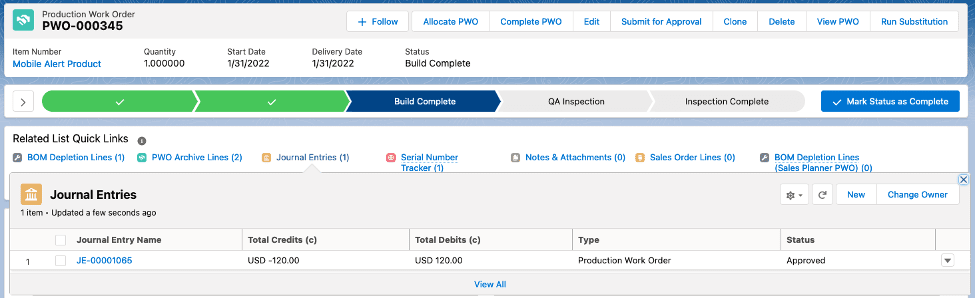

Hover over the Journal Entries (1) field:

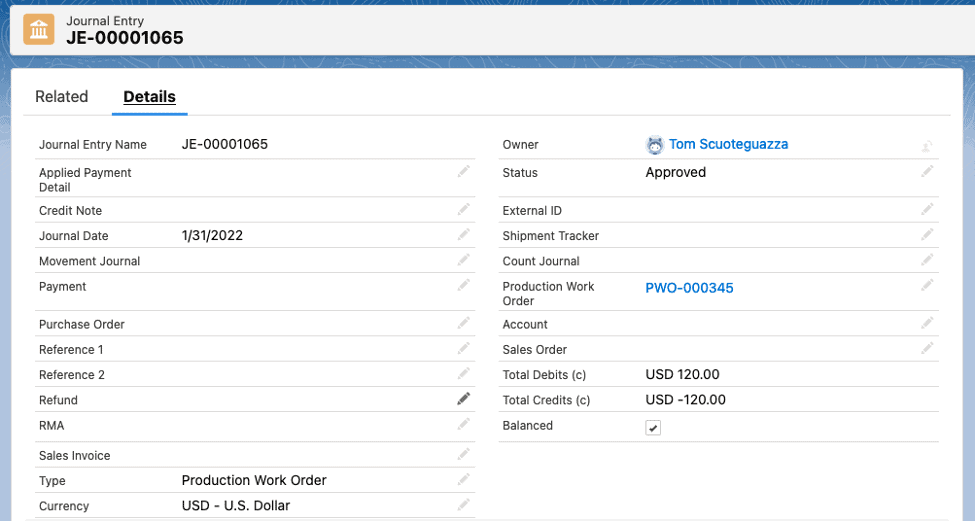

The journal entry that was created is JE-00001065. Let’s click into it:

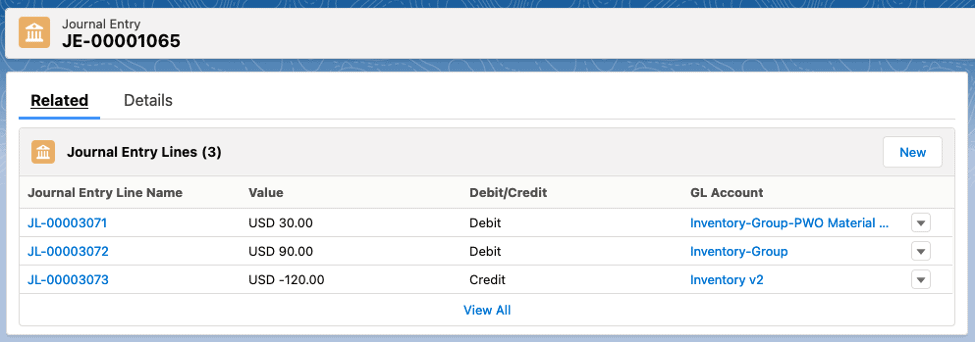

The journal entry has Total Debits of $120.00, and Total Credits of -$120.00. Select Related to see more detail:

You’ll see three (3) journal entry lines. Since this is an item with a standard cost type, the $90.00 is the DR to Inventory-Group, which is the inventory account for the BOM item. The CR is to Inventory v2, which is the component inventory account, and that $120.00 is the total value of 4 consumed times $30.00 per unit consumed. The DR for $30.00 is the difference between the standard cost of the BOM and the sum ($120.00) of the 4 consumed components.