Returns – Vendors

Overview

Inevitably, material purchased, if not proper quality or if no longer required, will be returned, whether it is being returned by a customer or being sent back to a supplier. Ascent has three overall combinations of data objects that can be used to return material:

- Returns and Return Lines

- RMA (Cases) and RMA Lines

- RMA (Cases) and Return Lines

RMAs would be used if a company uses Salesforce Cases, and would like to continue to use them. That would also mean that the user would have to have a Salesforce Enterprise license.

Returns would be used if a company’s warehouse people don’t have or don’t require a Salesforce Enterprise license, and can use a Salesforce Platform license.

In the Custom Settings section of this document, we will discuss how the different options can be set.

NOTE: for this document, we will be discussing Returns and Return Lines.

Definition: A return, as stated before, is a way that material can be returned to a supplier or received back from a customer. It consists of a return header (called a return) and any number of return lines (called return lines).

Returns can be generated in the following ways:

- From Sales Orders by clicking the down arrow next to the Change Owner button on the Sales Order screen and clicking Create RMA

- From Purchase Orders by clicking the down arrow next to the Change Owner button on the Sales Order screen and clicking Create RMA

- Manually create a Return and a Return Line. This is useful when there exists no Sales Order to create the return nor is there a purchase order to do that, either.

On a return line, there are many different types of returns:

- Return: This type of return is used to record the return of material to a vendor from inventory. It will record the return and make that information known to the purchase order line. It does NOT change the quantity ordered on a purchase order. It does NOT create a new purchase order.

- Replace: This type is used to replace items that have already been returned from inventory via an RMA return type. You would reference the same purchase order line that you’ve already created an RMA Return for, and make the type “replace”. When this occurs, you create a new purchase order line for the quantity to replace. You can then receive that NEW purchase order. ‘Replace’ is typically done as part of a two-step process (Return and then Replace) when your vendor requires inspection of the material before agreeing to replace it.

- Replacement: This type of return is used to do the return and replace in one step. When you use this type, the quantity is returned from inventory and the original purchase order gets a return line for the return. The new line is created as being already received. The net change to the quantity on hand is zero (0).

- Replacement from Order: This type of return operates differently than the way a replacement type acts; it creates a NEW purchase order, a NEW purchase order line, unlike a replacement type which creates a new purchase order line on the original purchase order, and the NEW line that gets created MUST be received. It does not get created with the line already being received. When it is received, the net change to the quantity on hand is the quantity received on the NEW purchase order line.

- Reverse: This type gets used only AFTER a Return or Replace has been processed. The Reverse would take the Return, for example, and physically remove the reverse line from the purchase order and put material back in stock.

Custom Settings: there are a number of custom settings which can affect how a sales order works. Some of them will be outlined here. A few are discussed later on in the body of this document. To see all possible custom settings, please review the Custom Settings document.

- Create New Order for Replacement RMA – When adding a line to an RMA/return, the RMA Line Status is “Replacement” or “Replace-from Order” and if this custom setting is checked, that RMA/return line will create a new purchase order. This becomes useful if a completely new purchase order is required.

- Show Print on RMA Lines view – This custom setting enables the Print button in the Action section at the line level in the VF page Return Lines View and RMA Lines View. This permits printed documentation for the line being returned.

- Show RMA Line Id – This is for RMA Lines View and Return Lines View visualforce pages. When this setting is enabled , there will be a new column showing up in these pages that will show RMA or Return Line Id.

- Show Unit Quantity – Enable this custom setting if you want to show total Unit Quantity column on interfaces such as PackSO (packing a sales order), Process RMA Lines / Process Return Lines, ReceivePO (receiving a purchase order), and almost all interfaces where quantity is involved.

- Use Serial Number Detail – If this custom setting is checked, then every time activity occurs for a serial#, a new record of the activity gets written out to the Serial Number Detail object. This becomes very useful when analyzing returns for an item.

- Use Returns And Cases for RMA – Creates a matching Case and Return record when trying to return items. 1 to 1 relationship between returns and cases.

- Use Returns – Allows users to use the Returns object in lieu of CASE. Does not need a full Salesforce license.

- Display Comment Field on View RMA Lines – Once enabled, a comment field will appear when adding/changing/deleting an RMA Line. This could be useful to specify why material is being returned.

- Don’t close a return if it has Open Lines – If a return is linked to a CASE, and the CASE is closed, if this setting is enabled, the return will remain open and will not close until all lines are processed. Often, a company will use a CASE as the initiation point for a return, and a return will be created and linked to the CASE. Once the disposition of the CASE is determined, the customer service rep may close the case, however, the material may not have been returned, hence, the need to keep the return open.

Process

Since there are many ways to process a return, this document will have 2 main “Process” sections:

- Returns with Return Lines – Vendor Returns from Purchase Order

- Returns with Return Lines – Blind Entry for vendor return with no purchase order

These other 6 “Processes” will be documented in the RMAs/REturns documentation:

- RMA (Cases) with RMA Lines – Customer Returns from Sales Order

- RMA (Cases) with RMA Lines – Vendor Returns from Purchase Order

- RMA (Cases) with RMA Lines – Blind Entry for customer return with no sales order

- RMA (Cases) with RMA Lines – Blind Entry for vendor return with no purchase order

- Returns with Return Lines – Customer Returns from Sales Order

- Returns with Return Lines – Blind Entry for vendor return with no purchase order

We will not document RMA (Cases) with Return Lines, since very few customers use this hybrid mix, and they are really a function of the two main types.

Returns with Return Lines

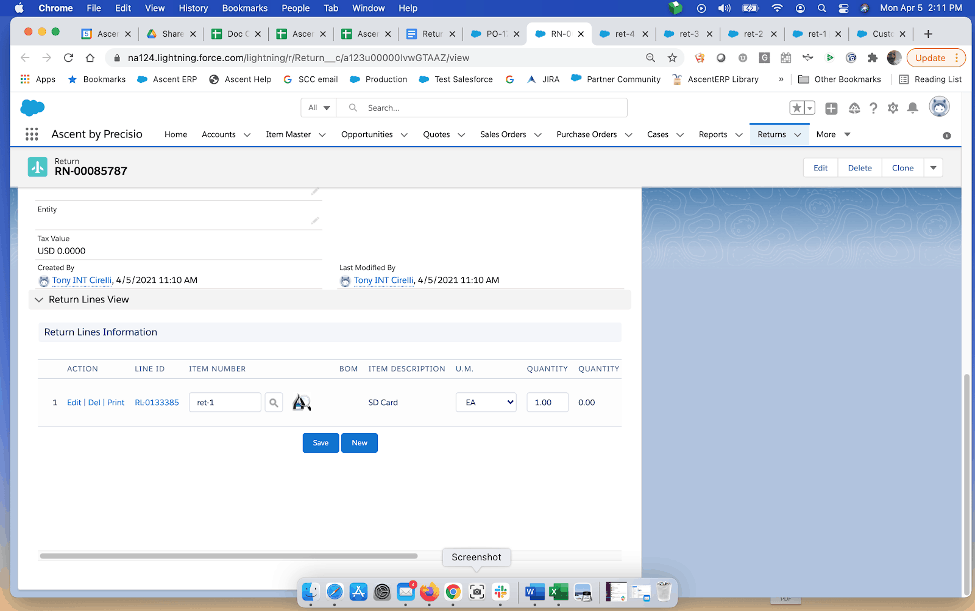

Returns with Return Lines – simple return

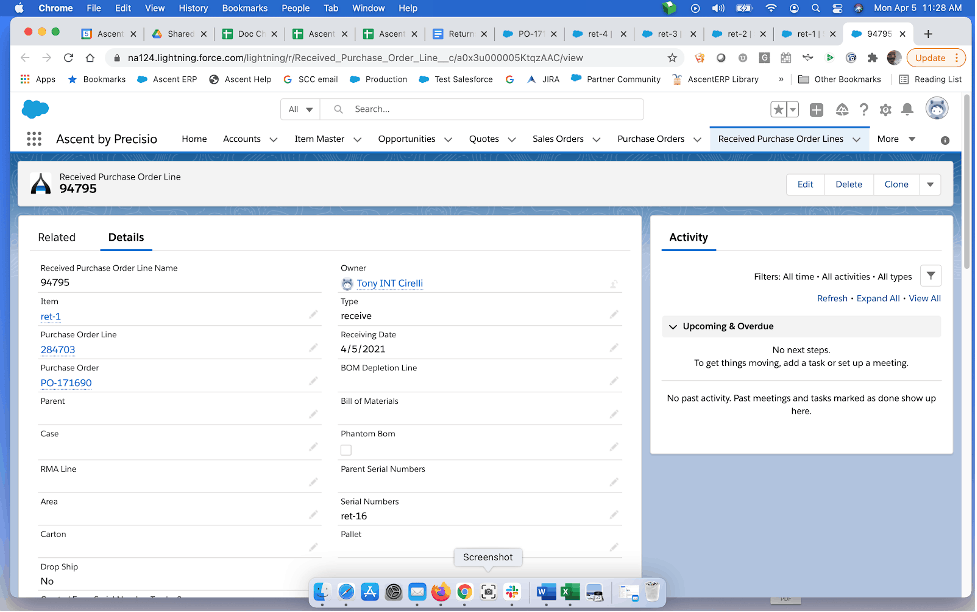

This is the simplest form of return. For this example, we will create a purchase order, add a serialized item, receive it, generate the return, and illustrate the return process. First, the received PO line:

We received PO-171690, line 1, item ret-1, qty=1, serial numbers RET-16.

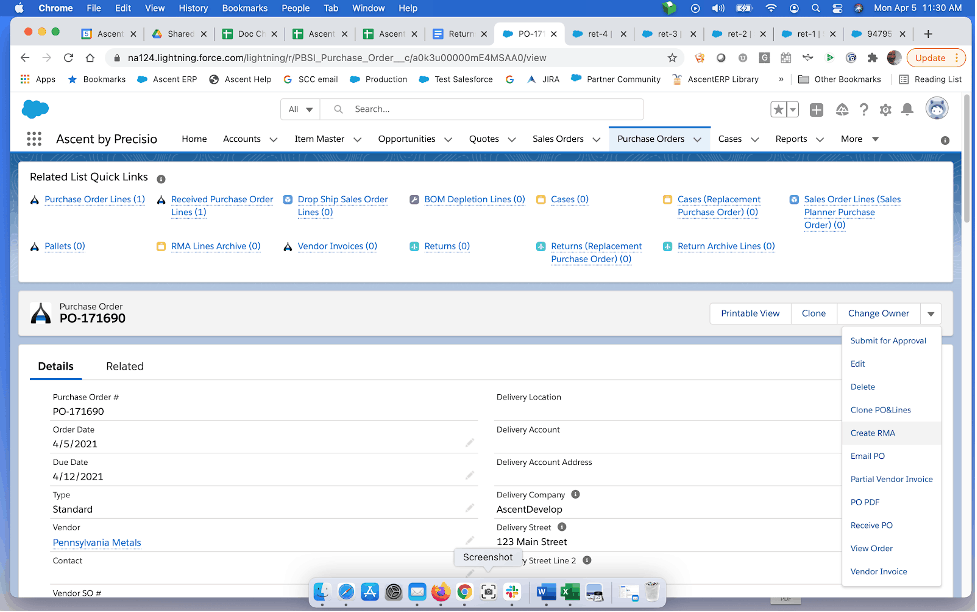

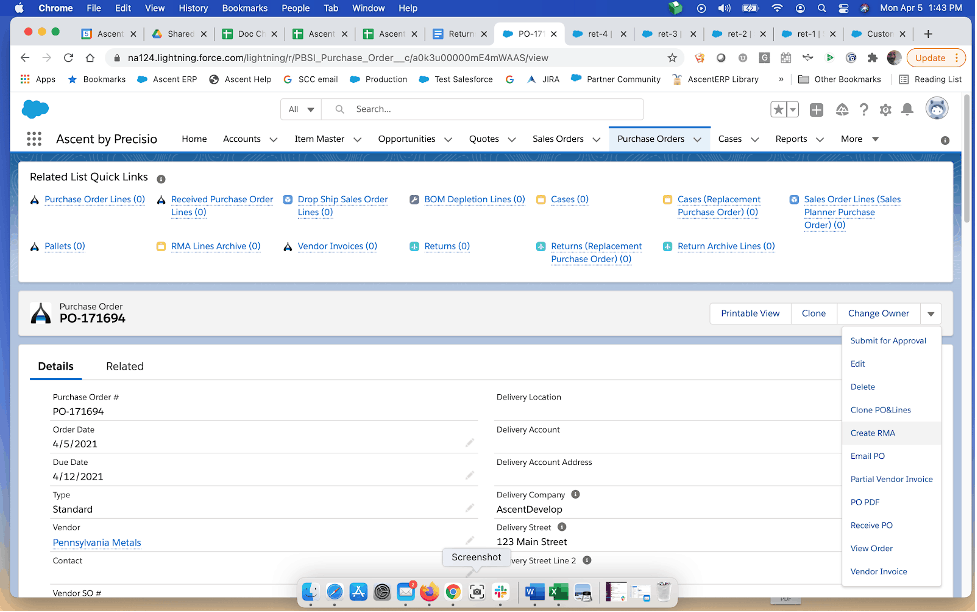

To create the return, go to the purchase order and click on the down arrow next to the Change Owner button, and select Create RMA:

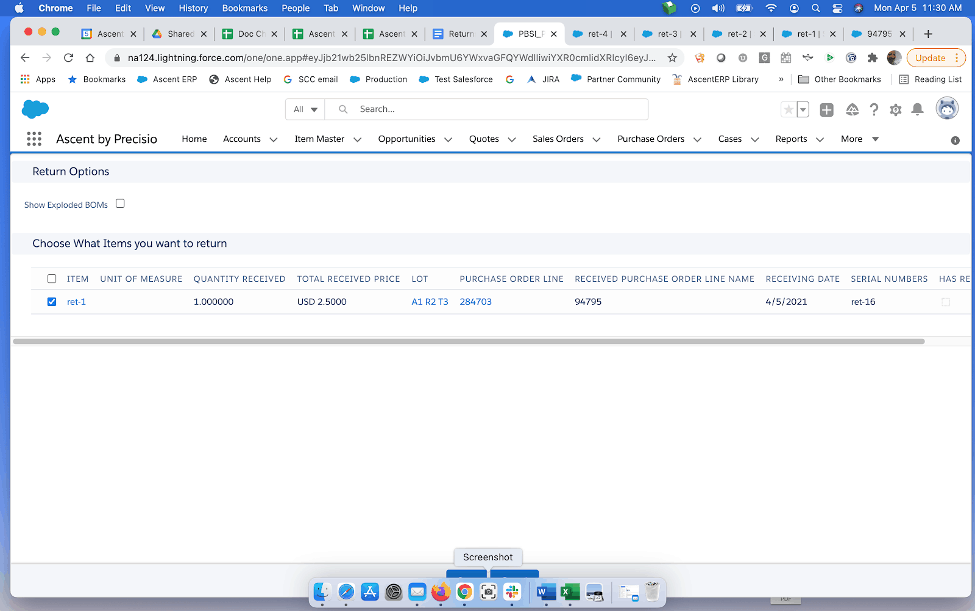

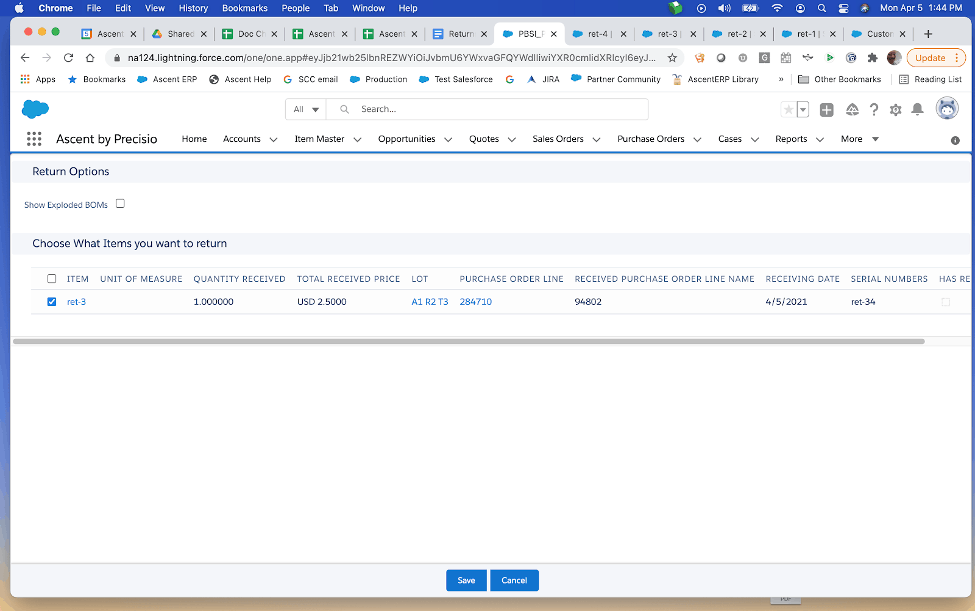

This screen will appear next, asking you to select those lines which you wish to have on the return:

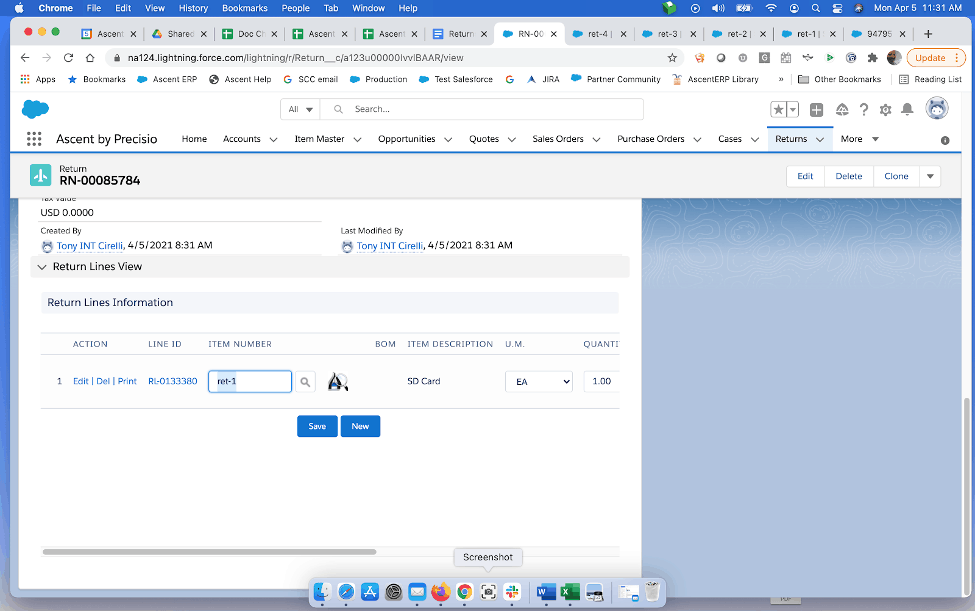

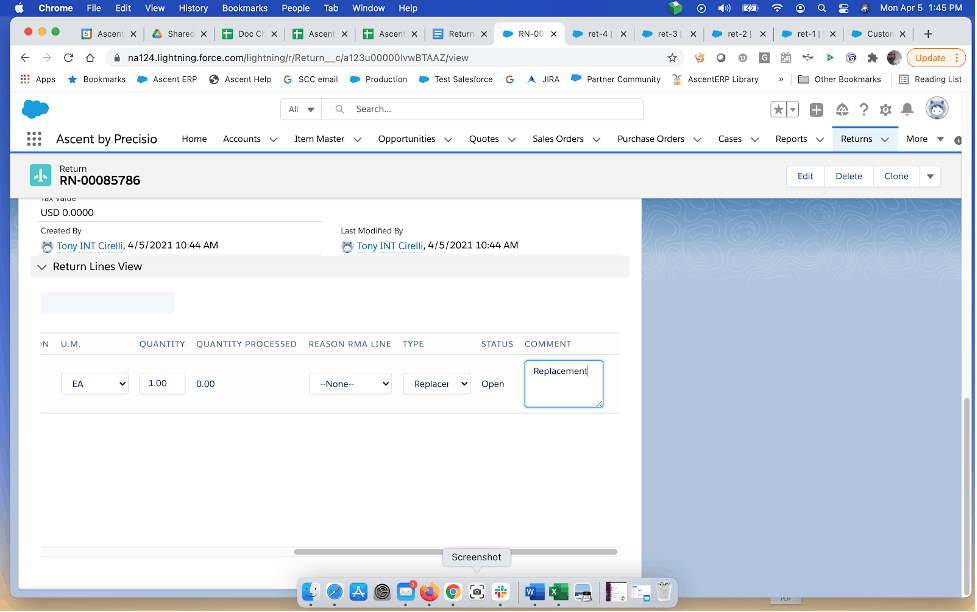

After hitting save, this screen will appear (the number of fields is quite long, so we’ve taken two screen shots to show them all:

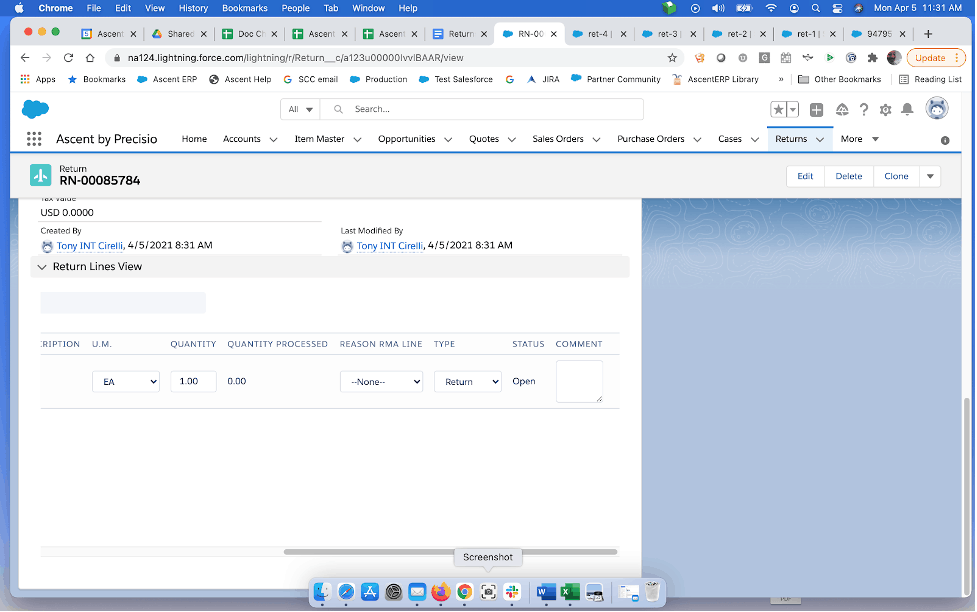

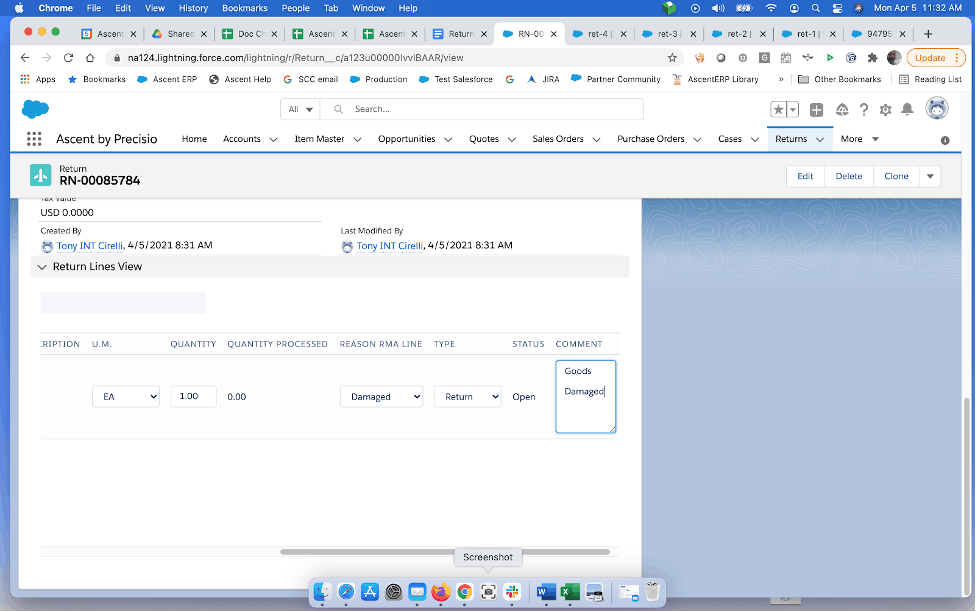

The system will default to Type = “Return”, which is what we want in this instance. The Reason RMA Line field is one that is a pick list, and can be customized by your system administrator. You can also add comments to the return line. Once satisfied, hit Save.

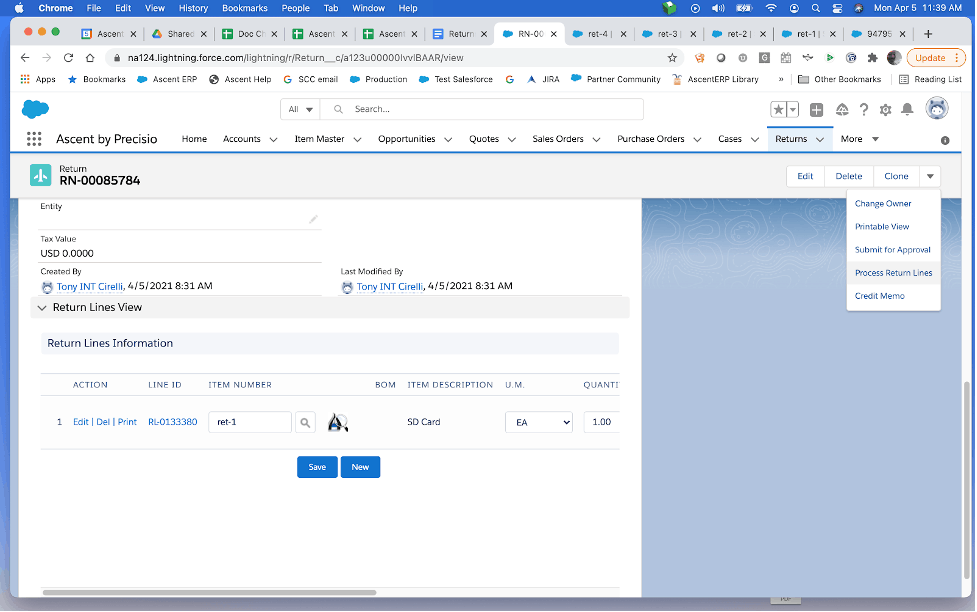

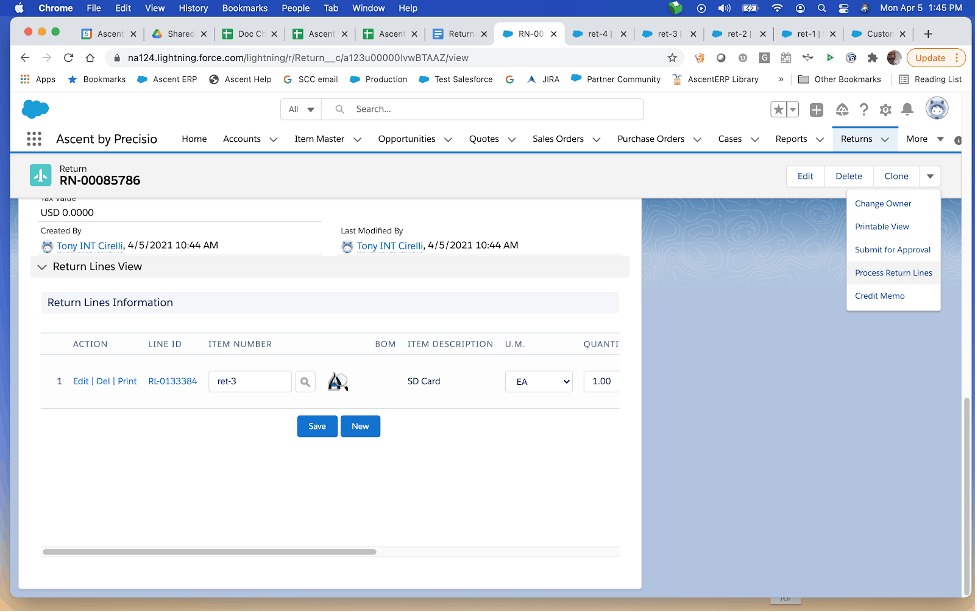

To process the return, go back to the return screen, and select the drop down arrow next to the Clone button, and then select “Process Return Lines”:

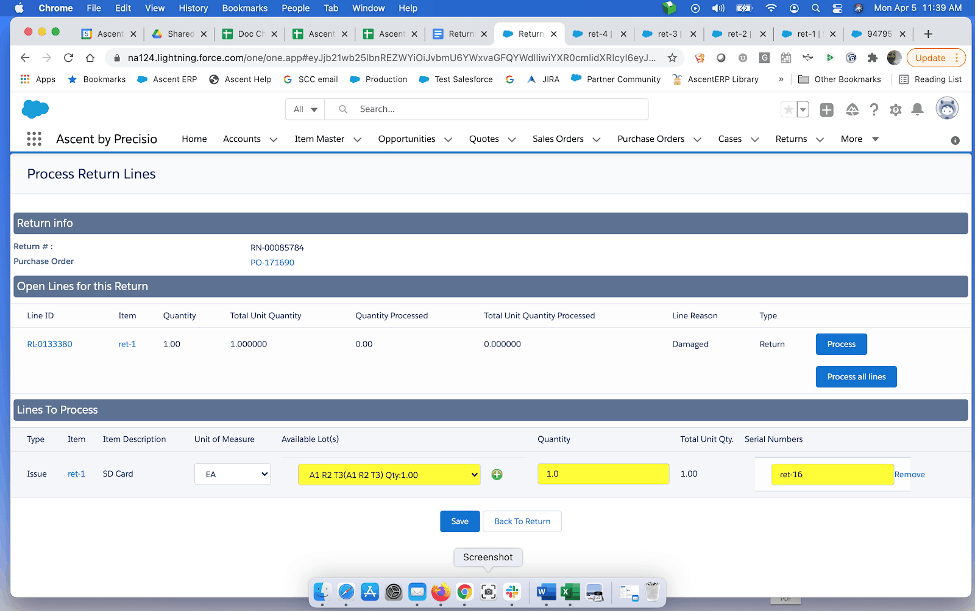

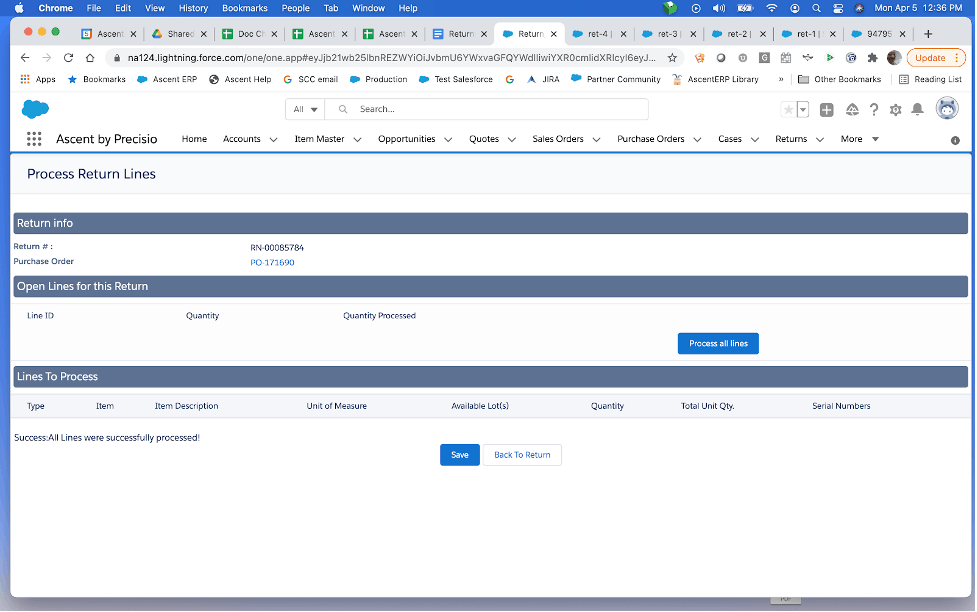

This screen shows the open lines, and Lines to Process, which appear after selecting Process:

The location is the one that the material was originally received to on the Receive PO process. The serial number is the one that was received on the purchase order. After hitting Save, you’ll see confirmation.

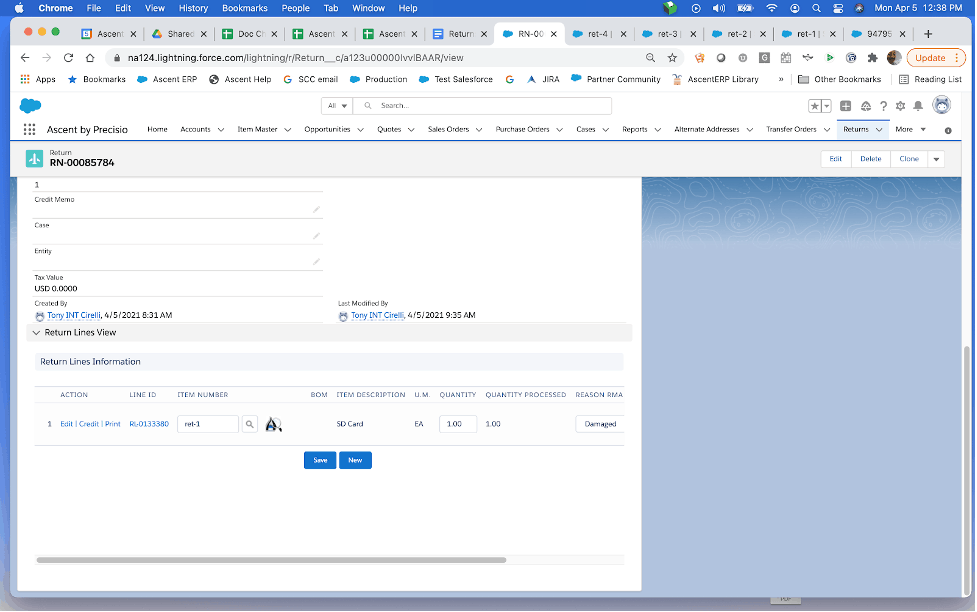

The return line will now show the Quantity Processed.

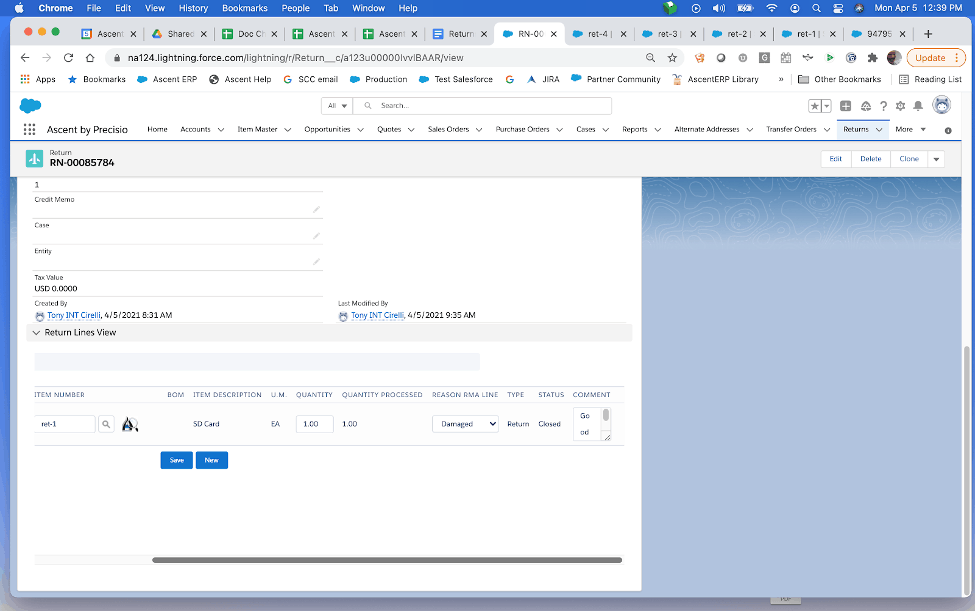

And if we scroll to the right, we’ll see the Status on the return line is now Closed:

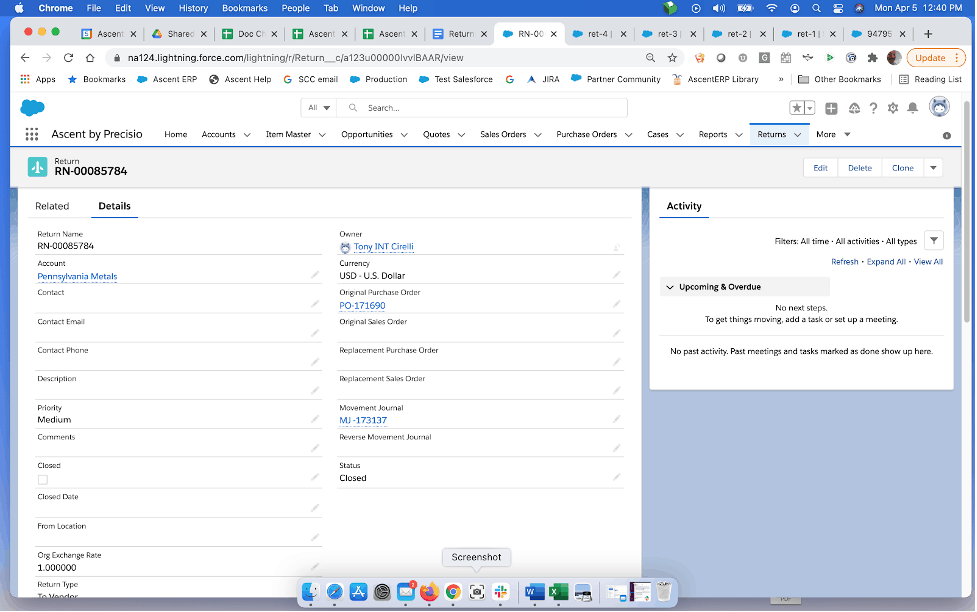

The Status of the Return itself is also Closed:

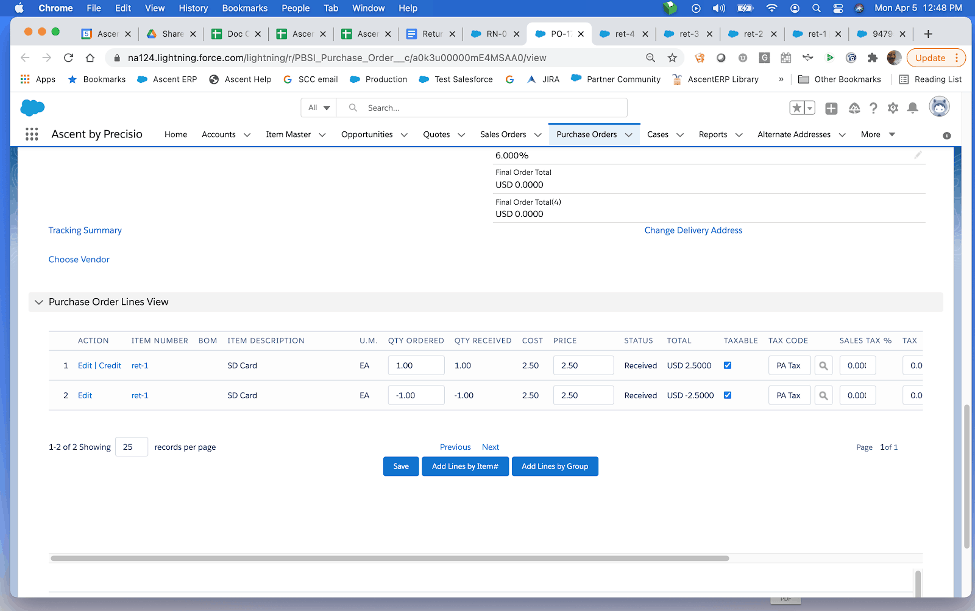

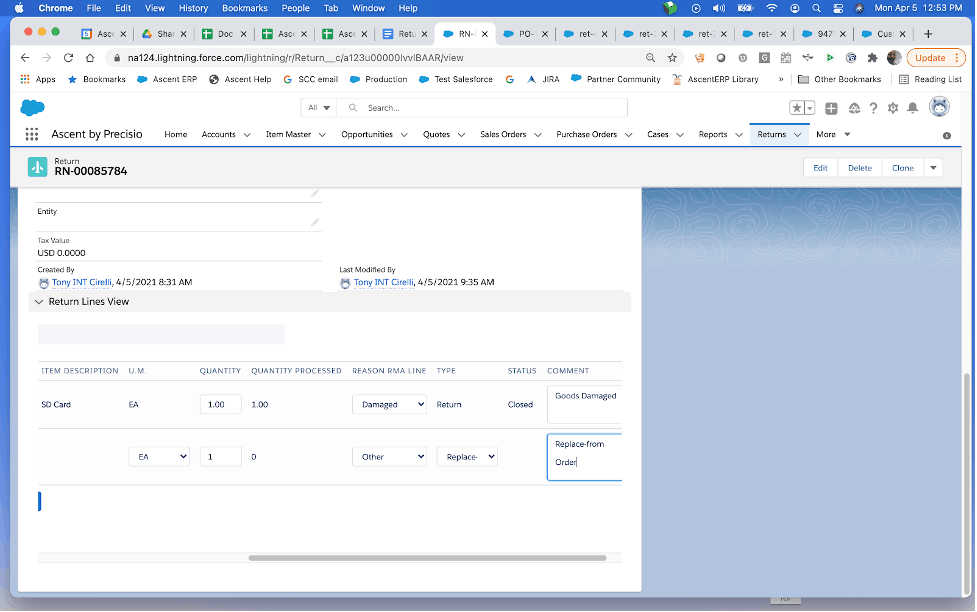

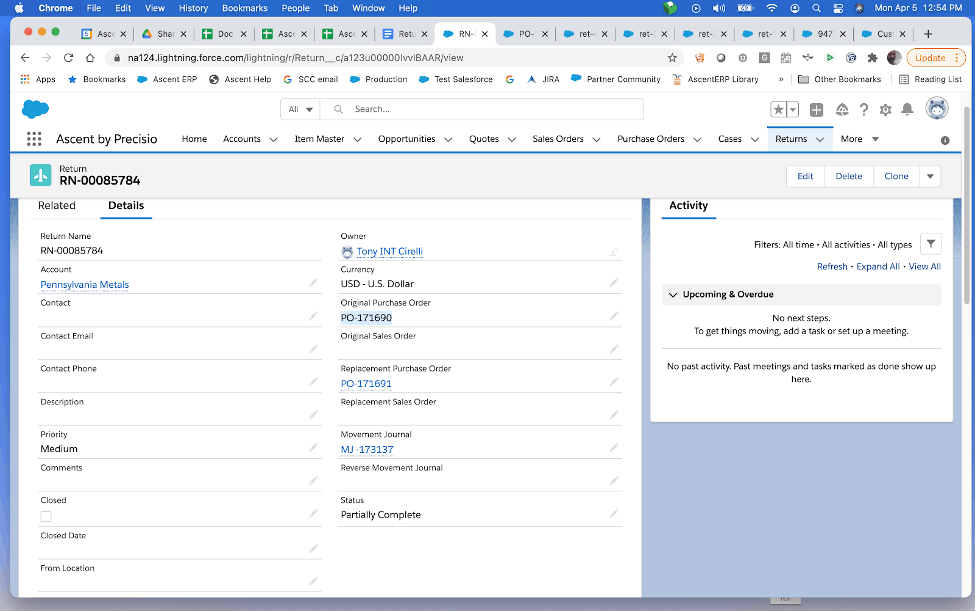

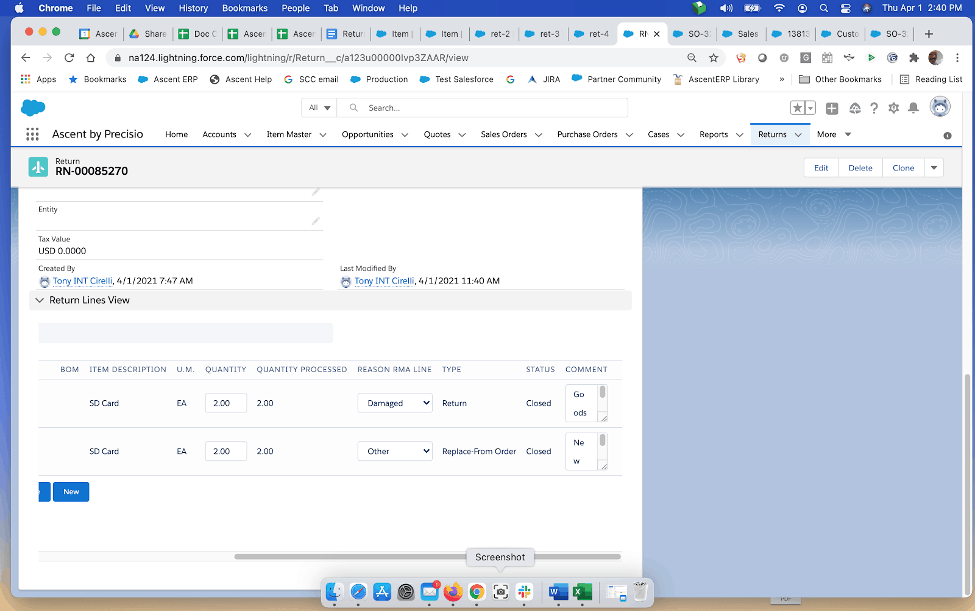

Returns with Return Lines – Replace-from Order: For this example, we are using the previous PO,

Do Not Add Credit Lines From RMA was not enabled, Ascent created a -2 quantity PO line.

Create New Order for Replacement RMA is enabled and by adding a new return line, a new PO is created.

Notice the Replacement Purchase Order field on the return:

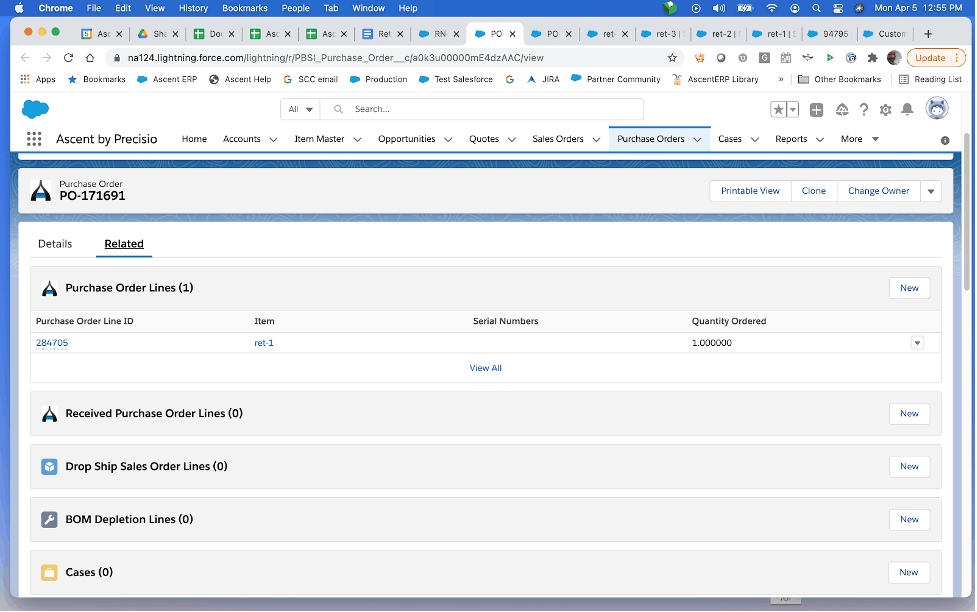

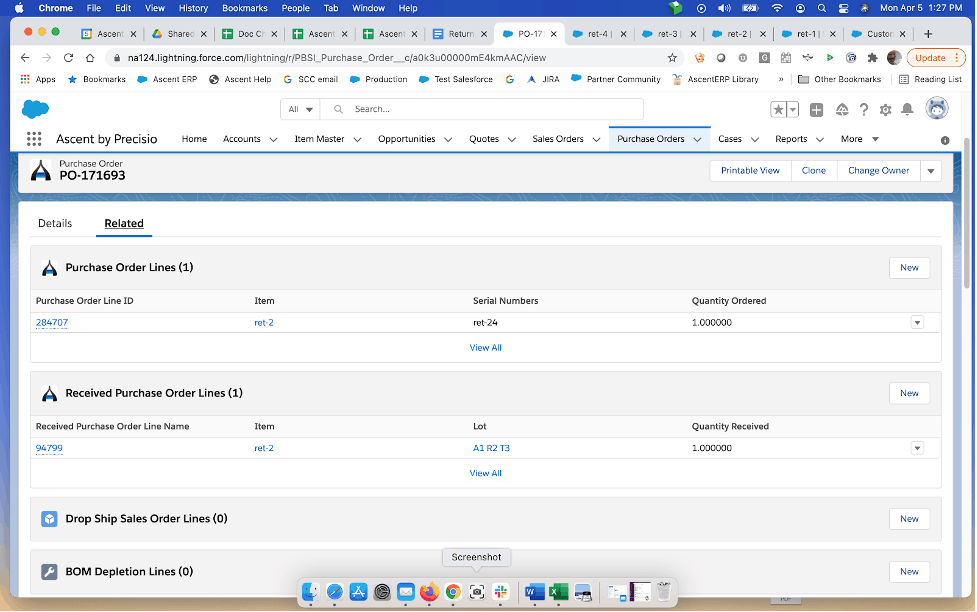

And the new PO and Line:

After performing Receive PO on the new purchase order, Ascent will update the newly added Replace-from Order return line. The status is now closed.

Returns with Return Lines – Replace – How to replace an item that has already been returned:

This situation would be due to the fact that many companies will not automatically replace material that is sent back to them from a customer until the returned item is inspected. In this case, we are the customer, returning material to the vendor. Therefore, the return and replace process occurs in two steps. This step will replace the material returned to the vendor.

Important notes:

- Processing a “Replace” will add a new purchase order line to your existing purchase order and perform a Receive PO on that new purchase order line.

- Custom setting Create New Order for Replacement RMA must NOT be enabled. If it is, you will get a NEW purchase order, not an additional line on the existing purchase order.

First, here is the received purchase order line:

We’ve now created a return, processed it, and here is the processed return:

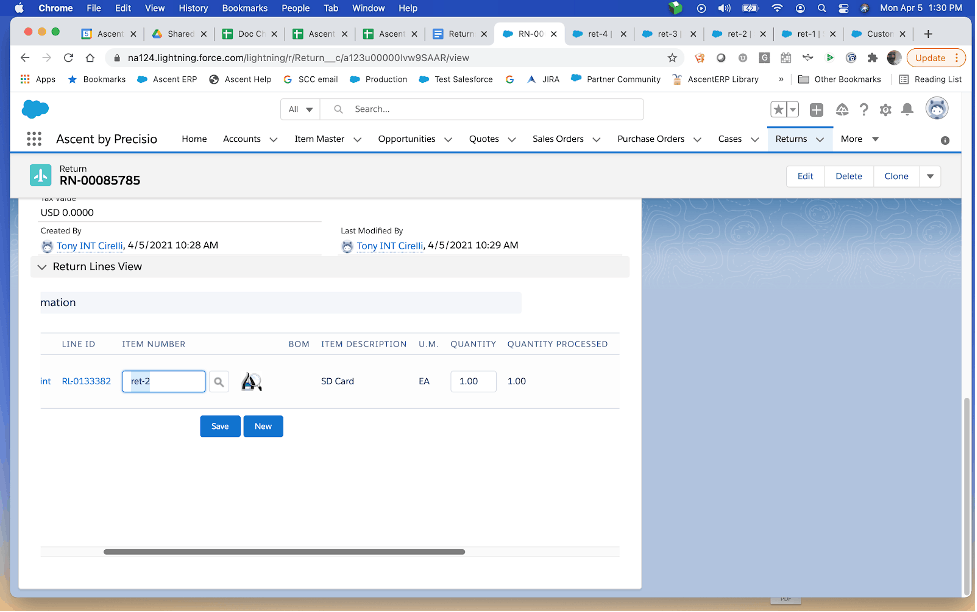

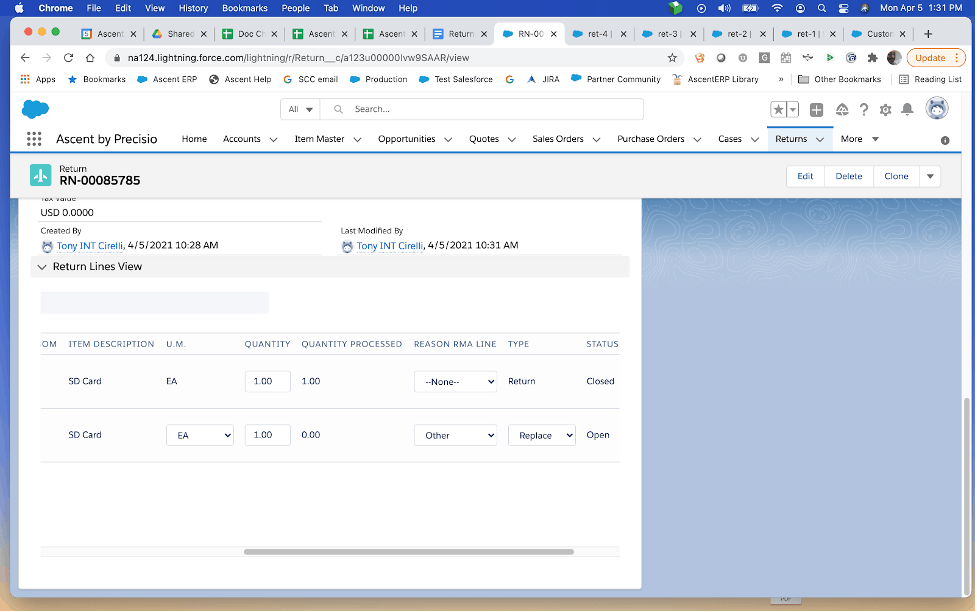

Now, add the “Replace” line to this Return:

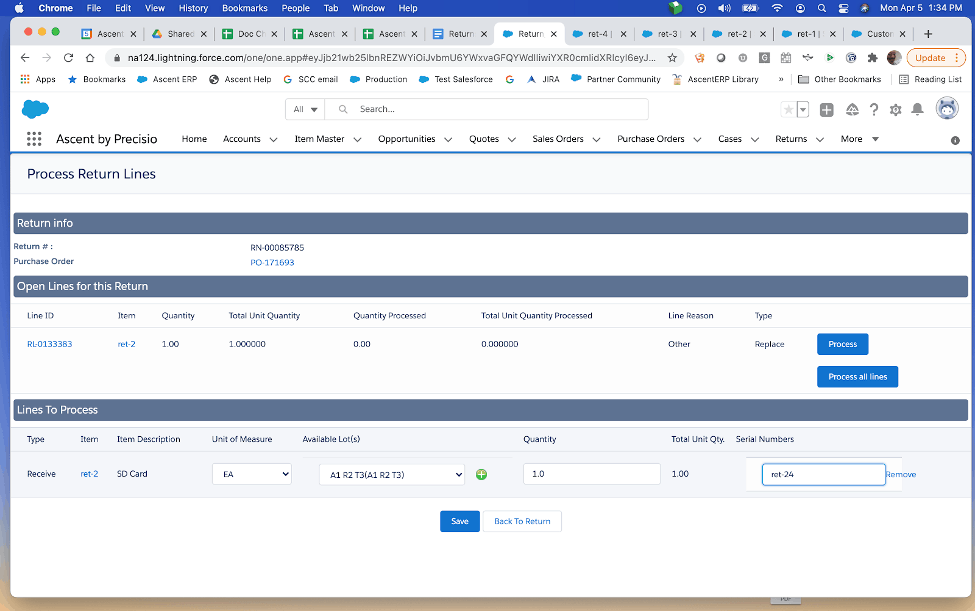

Now process the newly added “Replace” return line. Enter the serial number to be returned and Save.

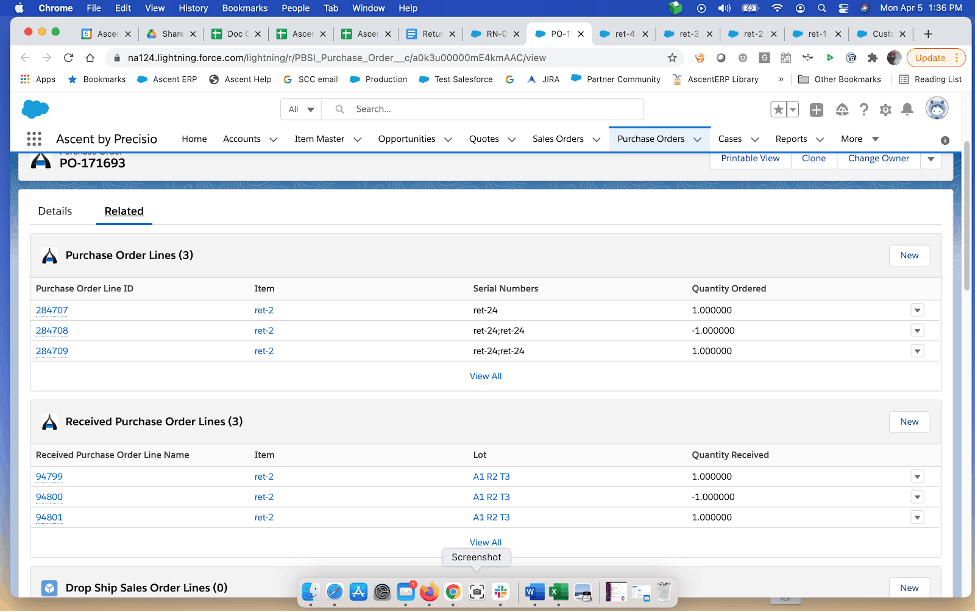

Look at the originating purchase order. A new PO Line has been added and received:

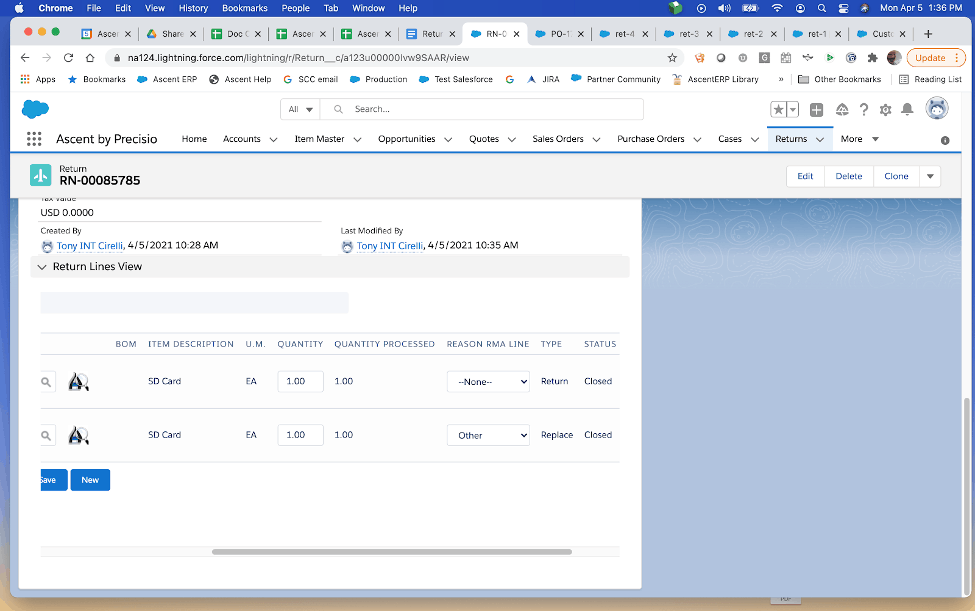

Looking at the return “Replace” line, it now shows as closed.

Replacement – Return and Replace in one step:

To make this work, the custom setting ‘Create New Order for Replacement RMA’ must NOT be enabled, or else you’ll create a new purchase order. The intent here is to ask you for the item and serial number being returned as well as what it is being replaced with.

First, here’s a received purchase order:

Next, create an Return for it by selecting the down arrow next to the Change Owner button and hitting Create RMA:

Select the line to return:

Here is the Return line that was created. Change the Type to Replacement and hit Save:

Once saved, select the down arrow next to the Clone button and choose Process Return Line:

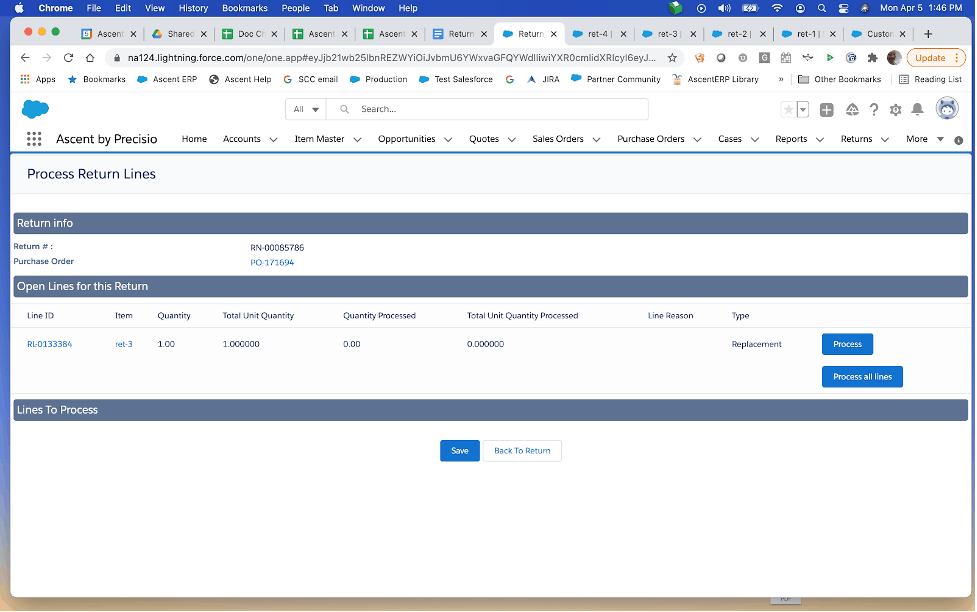

This screen will appear, and you can select Process:

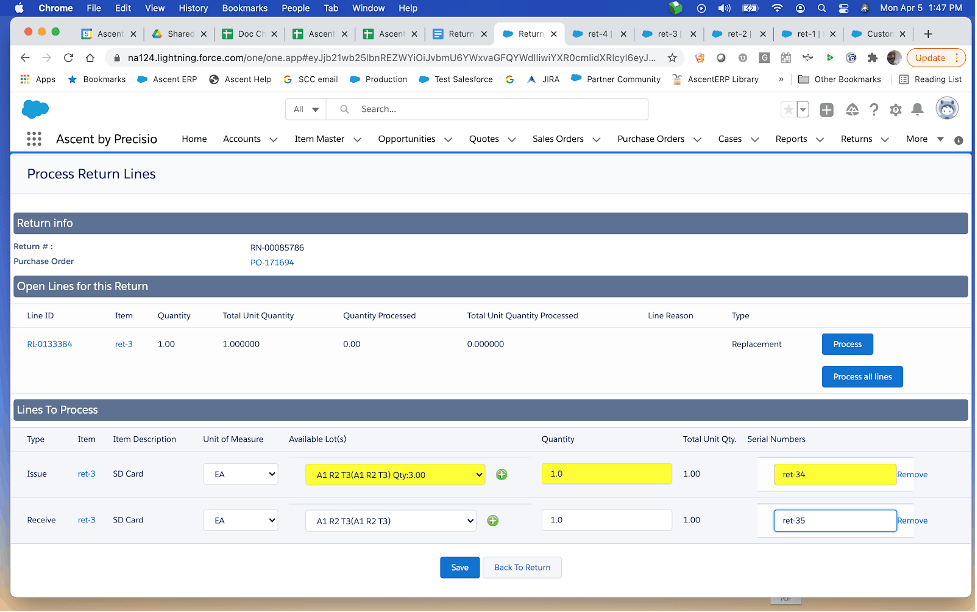

You’ll see 2 lines, one for the return and one for the replacement. Enter the serial number which is the replacement and hit Save:

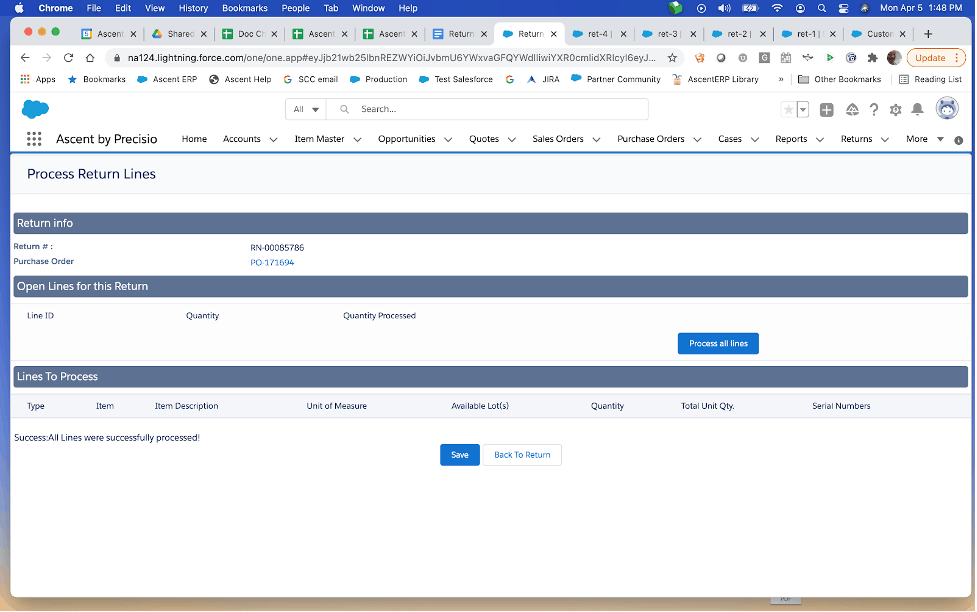

You will get a confirmation message:

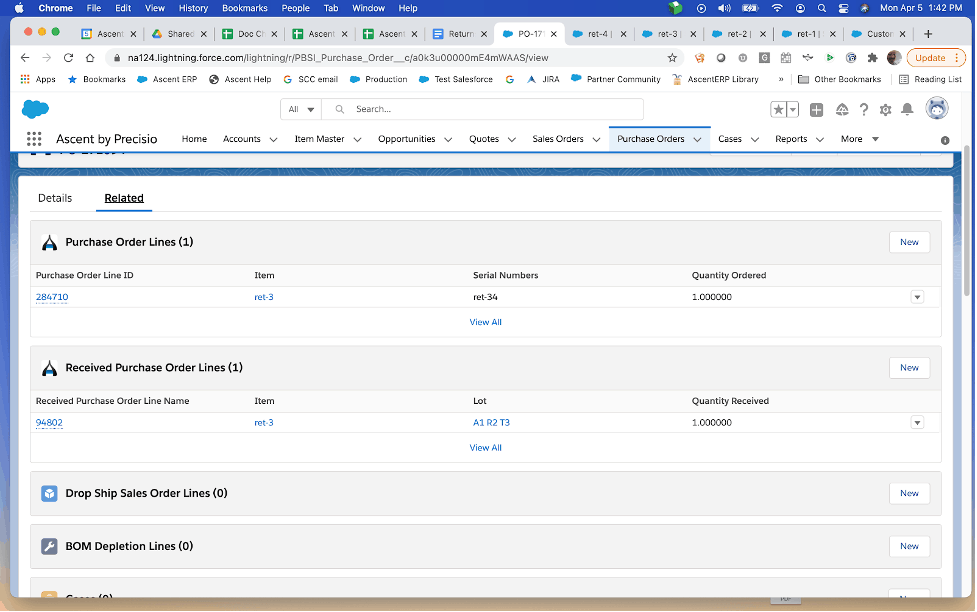

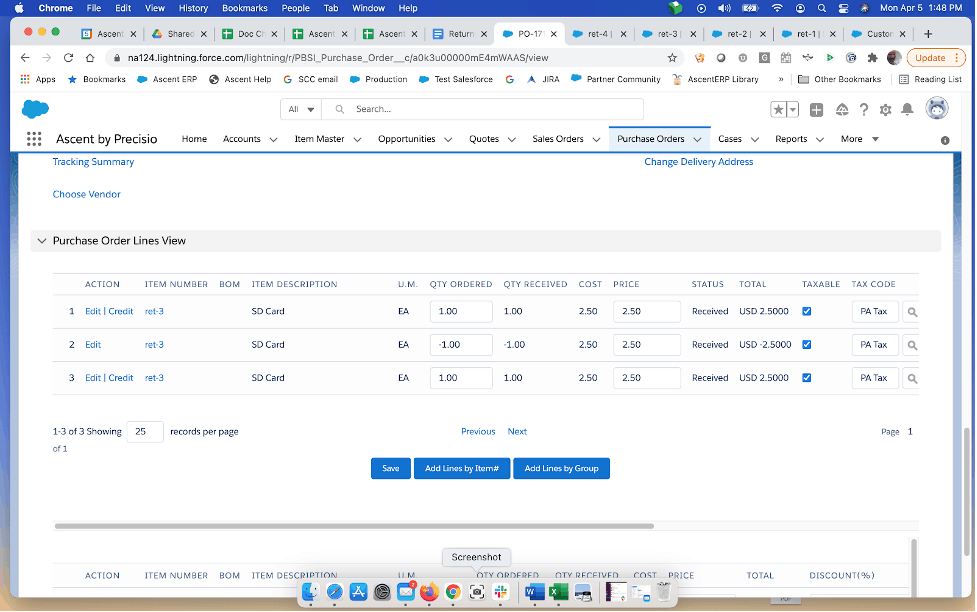

The originating purchase order will show the PO line added to act as the replacement.

Also on the purchase order you can see both serial numbers being referenced – the one being returned and the replacement.

Creating a Return for an individual purchase order line:

The above examples had a single purchase order line on each purchase order. This was done to simplify the illustration. In reality, most companies will have more than one purchase order line per purchase order. Not every received purchase order line will need to be returned. Using the Create RMA button on the purchase order will create a Return for ALL the received purchase order lines. By going directly to the purchase order line containing the item you wish to return, you will not have to address the successfully received lines.

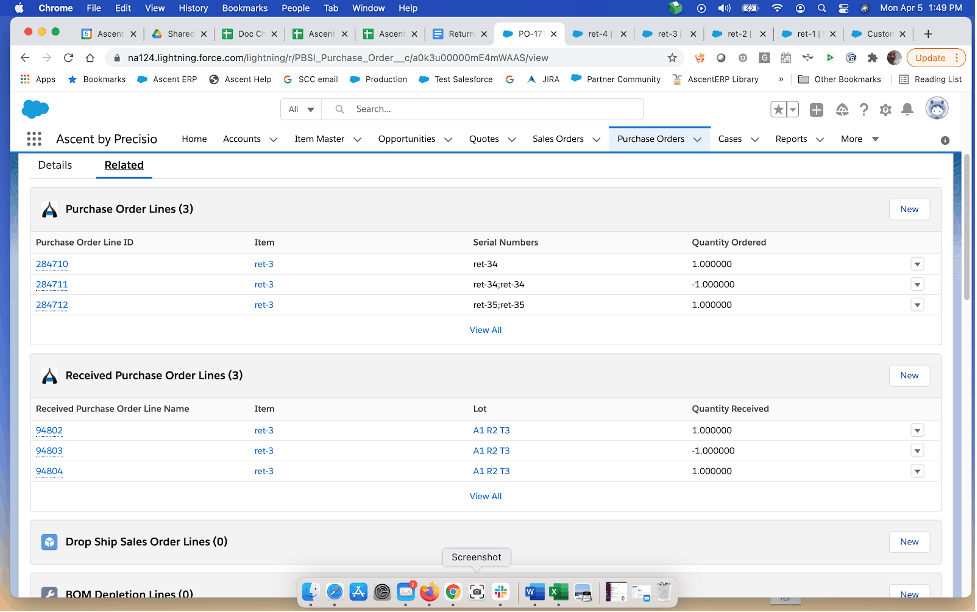

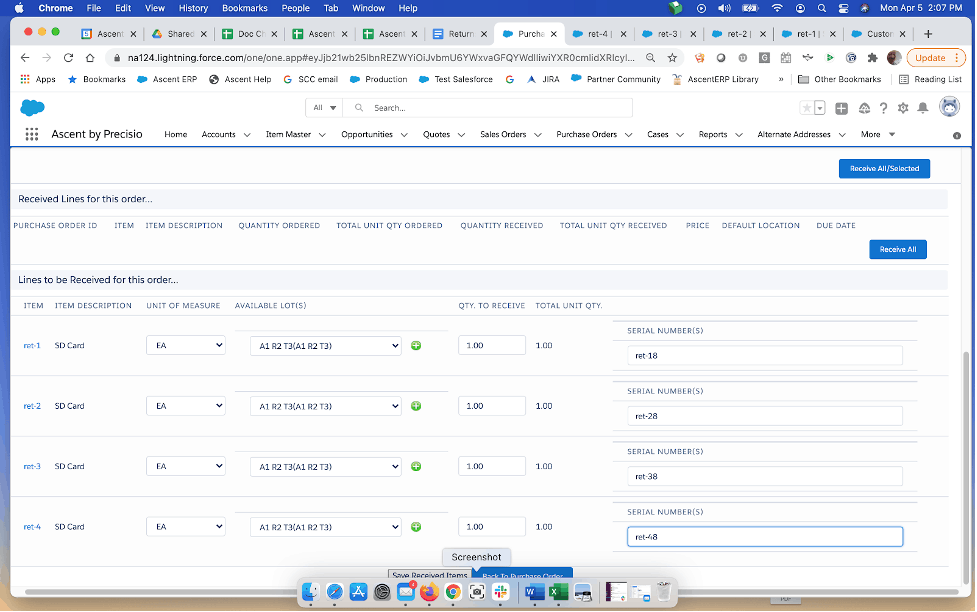

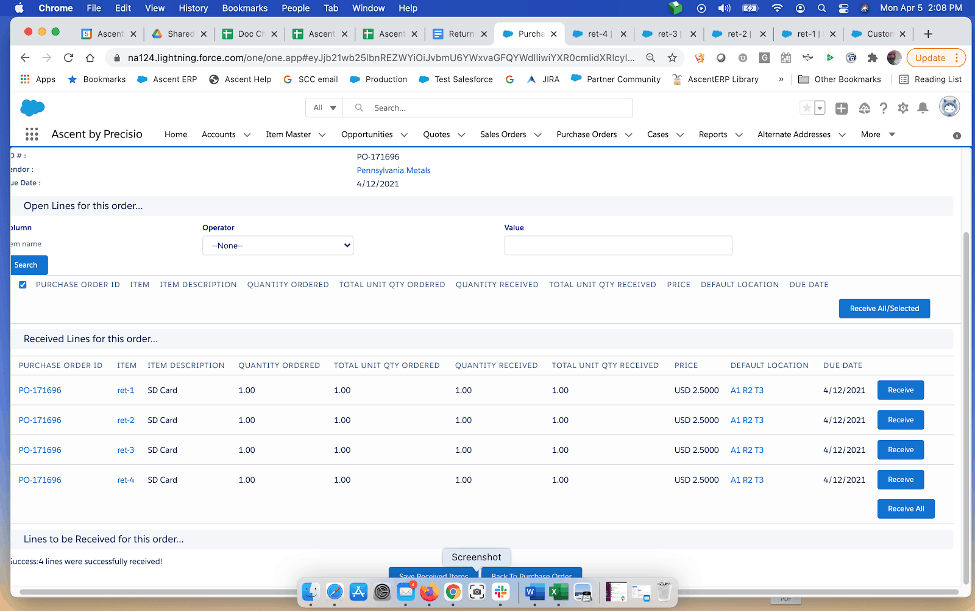

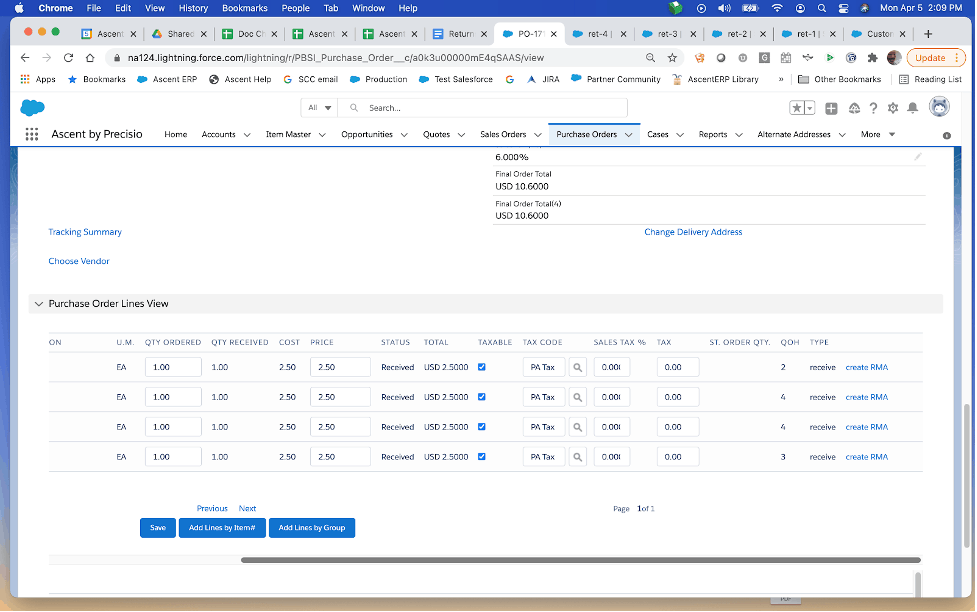

This example has 4 purchase order lines and here is the receiving process:

Here are the received purchase order lines:

In our example, we’ll return the first line. Go to the purchase order line, scroll to the right, and view the button titled create RMA:

Select that create RMA button and a return will be created:

The originating purchase order will show the above return. From this point on, you can process the return using any one of the processes documented above.

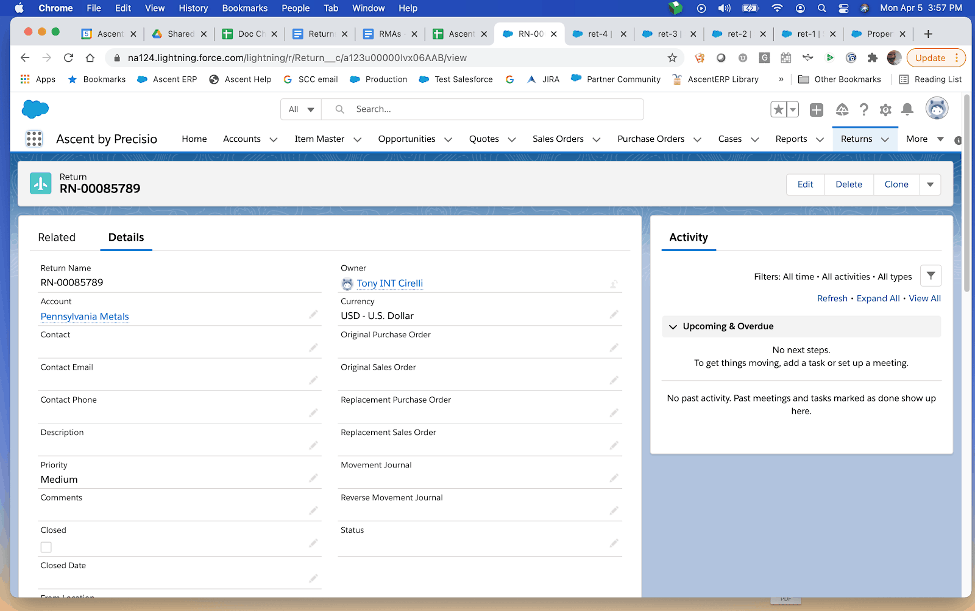

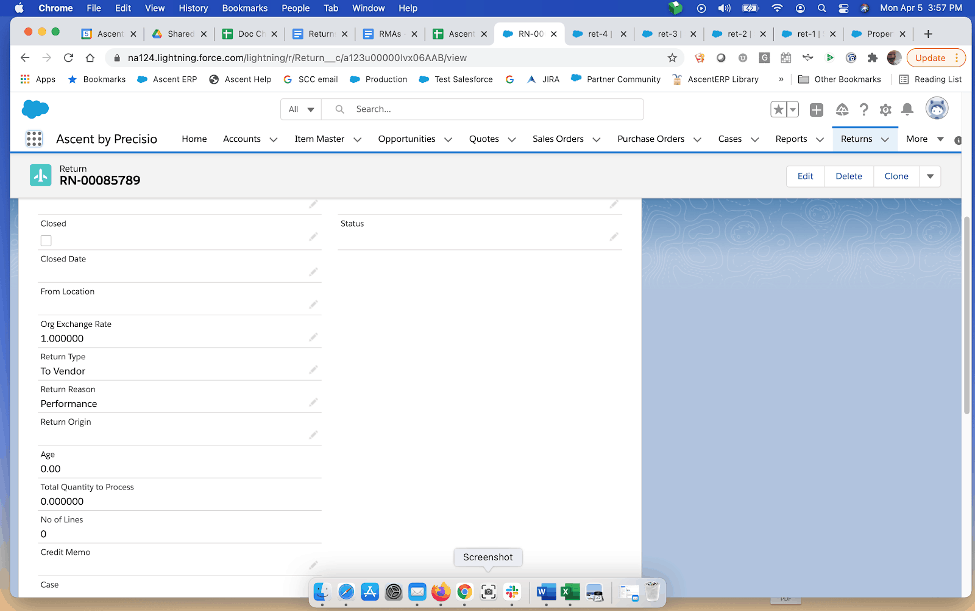

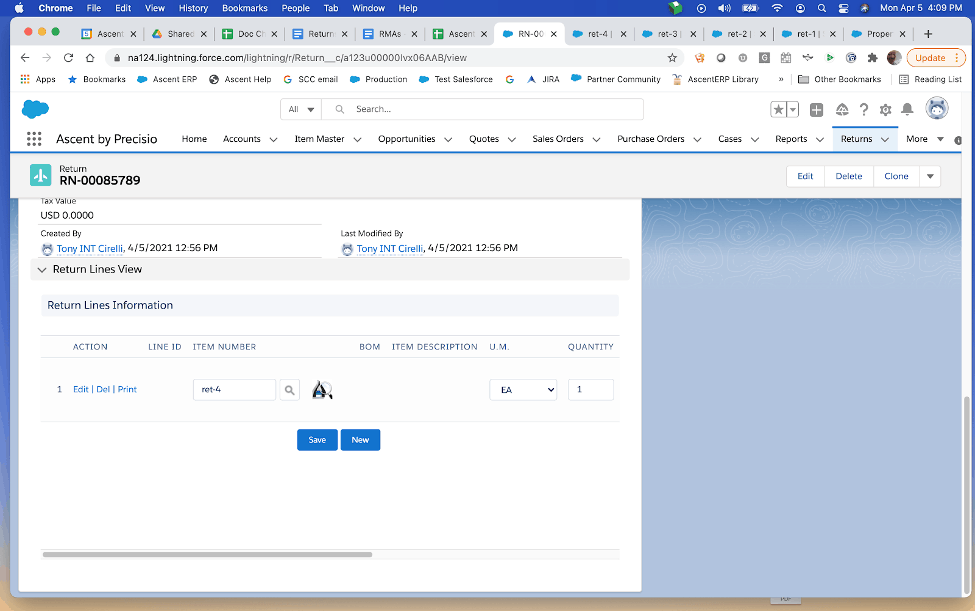

Returns with Return Lines – no reference to previously entered sales order:

When a company first starts using Ascent, they don’t have any already packed sales orders or received purchase orders to be able to reference to create a return. So, one must manually create the return header and return lines. First, create the return header. You must select an Account and a Return type (From Vendor). All other fields are optional, although entering a Return Reason would be good. To do this, select Returns and select New:

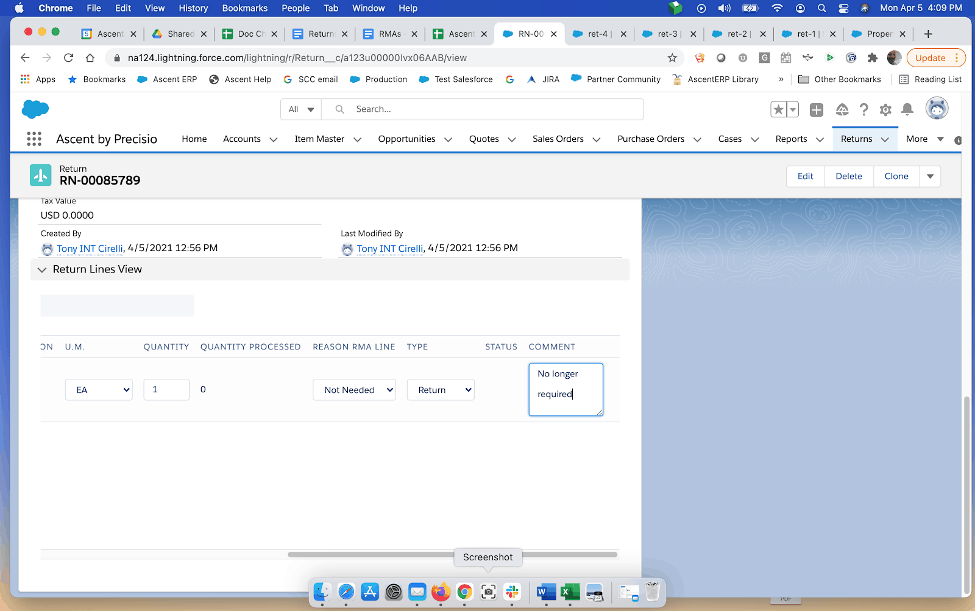

You must also add one or more return lines, by selecting New from Returns Line View:

Scroll to the right to update the Reason RMA Line and add a Comment.

From this point on, you can process the return in the same manner as any other return. The difference would be that those functions which update an existing PO cannot be done, since you would not have an existing PO.

If you wish to created a PO to replace the material returned to the vendor, you can follow the directions above for Returns with Return Lines – Replace-from Order.