Production Work Order Overview

Overview

This document will serve as an overview of all of the functionality available via Production Work Orders (PWO). Subsequent documents will discuss in detail all the features offered via PWOs.

Definition: Production Work Orders are objects/records in Ascent that serve as a framework for building/assembling/manufacturing assemblies and consuming the material that goes into that process.

PWOs consist of a production work order object/record and BOM Depletion Lines. The PWO object contains information pertaining to the BOM being produced, start/end dates, quantity to build, quantity remaining, material movement journal names, and inventory locations, among other things.

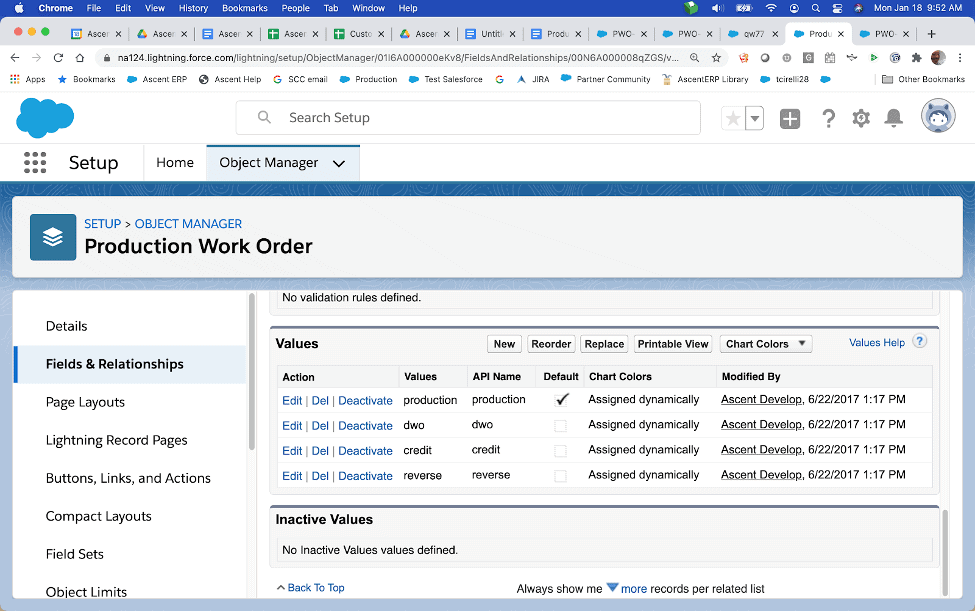

Types: the type field indicates how this PWO is to be used:

- Production – This is the typical order. It is used to build an assembly using the components.

- Credit – This type is used when you wish to reverse out the entire production work order’s completed quantity. For example, if your PWO had a quantity to build of 10, but you completed 3, and now determine that these 3 were completed in error, you can select “Credit” and the inventory that was consumed will be put back in stock, and the completed quantity will be removed from stock. You cannot specify a quantity to be credited. This function will credit the total quantity completed. Serial numbers created will remain on file, however, will not be counted in stock. Serial number records of the components will now be recorded as being in stock.

- Reverse – same as “Credit”, just a different name.

- dwo – Deconstruct Work Order – this type is used only when first creating a PWO. A PWO cannot start out as type = production and then be changed to this. A dwo is used when you wish to reverse/credit a specific quantity of assembled goods, whether those goods were made inhouse or whether they were returned from a customer. Sometimes, goods returned from a customer are not completely usable, so a tear down is required to salvage specific components/sub-assemblies, and scrap the remainder. On a dwo, you will be asked for the serial number being deconstructed (if the top level is serialized) and the components which are being put back into inventory’s serial numbers.

Detailed documentation: Each listed below gives detailed information.

- Creating Production Work Orders – Click Here

- Complete PWO – Click Here

- Allocating PWO and Building Allocated Quantities – Click Here

- Deconstruct Work Orders – Click Here

- PWO Substitutions – Click Here